Here’s One Way to Cash in on Micro Medical Advances

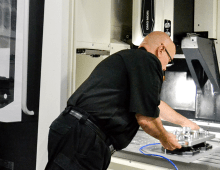

In the latest edition of their Medical Manufacturing Yearbook, Manufacturing Engineering featured an article by our very own VP of Sales and Engineering, Jack Burley. In it he discussed the rapidly advancing and shrinking technology in the medical field and metalworking’s role in it.

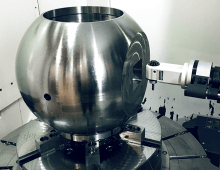

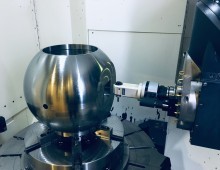

The Air Power Spindle offers variable spindle speeds from 100,000-120,000 rpm's simply through air pressure

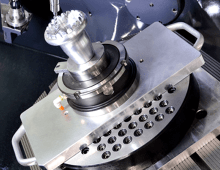

He explains that the drilling ranges of 0.5-2.5 mm now common in medical device production may seem daunting to some shops, but that with the right combination of tooling and equipment, most machines can achieve the speed and precision necessary to meet those parameters and cash in on this swelling market. Jack speaks specifically of the powerful pair of BIG Daishowa’s Air Power Spindle and micro drills from Sphinx.

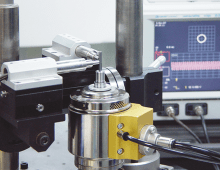

BIG Kaiser offers all types of designs of Sphinx micro drills beginning at Ø.05mm (Ø.002”)

Not only does the Air Power Spindle ramp up the RPM capabilities of a machine, but amazingly, it lessens lasting wear and in-process thermal disruption all while consuming significantly less power since the machining center’s spindle is not actually rotating. The spindle speeder’s partner in crime, the micro drill, faces the stiff challenge of maintaining our recommended 0.0025 mm maximum total indicated runout (TIR) in these types of jobs. Our Sphinx micro drills rise to the challenge by resisting heat and wear as well as managing tiny chips.

In the full article, “Shrinking Devices Grow Supplier Opportunities,” Jack goes in to much more detail about how the combo performs in this demanding space. It’s a combination that can give shops that thought it impossible, the opportunity to get their share of the micro medical device pie.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

Add new comment