Save Time and Money with OD Turning on a Machining Center

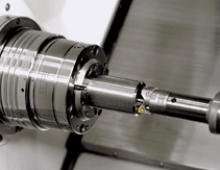

There are many advantages to turning (pun intended) to an underutilized operation that virtually every machining center is capable of: OD turning — otherwise known as “outer diameter turning”, “pin turning”, or “boss milling”.

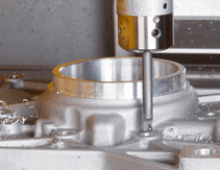

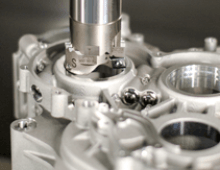

- Because of the irregular shape of this workpiece, it cannot have certain cylindrical features machined on a lathe. Thanks to OD turning, this casting can have all finishing features machined in one setup on a vertical machining center.

The most advantageous benefit is that you do not need to send the raw workpiece to a lathe for a turning operation….it can be done in the same machine, and the same setup, before you perform your other operations like boring, drilling, milling, tapping, etc. This not only saves setup time by not having to reposition workpieces — but is also helps to maintain part accuracies because of one less refixturing step. It will also reduce overall cycle time and further improve part quality due to more rigid clamping traditionally found on machining centers vs. lathes. Additionally, OD turning will provide a finer surface finish than circular milling.

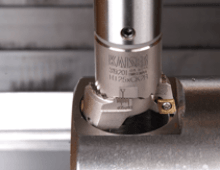

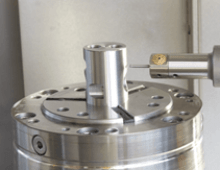

- Standard components from the KAISER boring system can create a “custom” tool setup in order to easily reach over a hub to perform this finishing operation.

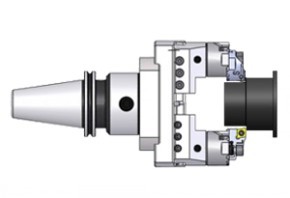

Through the use of a modular tooling system, like the KAISER system, creating long cylindrical part features is as easy as adding in extra components like extensions and counterweights for balance. And for diameters that are too large or too imbalanced for a traditional lathe, OD turning with the KAISER modular system is as easy as using a larger extension slide. You are only limited by the work envelope of your machine.

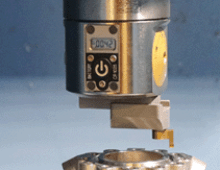

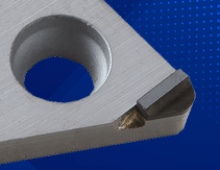

For initial roughing operations, two standard rough boring heads are used with a pair of insert holders oriented inwards. The dual cutting edges make the cut “two-edge effective”, providing higher efficiency. For final size and surface conditioning, a finish boring head, single point insert holder and counterweight are used in place of the roughing components. And since that involves lighter cutting loads, aluminum supporting components (like adapters, extension slides, etc.) can be used for faster feeds and speeds. Both rough and finish options are available with the KAISER modular boring system.

A recent call into our engineering department involved a customer with a somewhat tricky requirement — an OD turn on a Ø3″ cast iron workpiece that needed to finish at Ø2.5” — which the customer wanted to take all in one pass.

Here is how we did it:

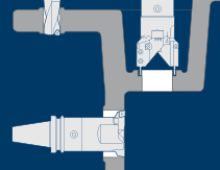

An OD turning tool was setup with standard KAISER components. Thanks to a design feature of our Series 319 rough boring system, both balanced cutting and stepped cutting can be performed with the exact same components. Step cutting allows for the heaviest possible stock removal, which is what we used. By following certain markings on the boring head and insert holders during assembly – DVS (variable height, or stepped) – the lead stepped insert holder was set to Ø2.75″ (at a .016″ step), and the trailing insert was set to the final diameter of Ø2.5″. Below is a drawing of the tools, and an illustration of the finished part.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.