Yes, You CAN Micromachine With A Standard Machine Tool

Early in my 25-year machining career, I worked as a machinist at a shop that did a lot of work on big parts. The owner invested in huge cranes and old equipment suited for that kind of work more often than he upgraded technology and machinery. Why not get the latest and greatest equipment, I asked? The owner explained that after the first job, the older machines paid for themselves – not because they were extra powerful or high-tech, but because no other shop in the area had that kind of equipment. Basic supply and demand.

In these odd times, when everyone is looking for new growth and savings, it’s especially important for businesses to revisit such fundamentals. What makes your shop different? How do you add value? Can you relatively easily and inexpensively expand your shop’s capabilities?

For one of the most accessible and impactful opportunities today, think like my former employer but look at the opposite end of the machining spectrum: micromachining. While just about any shop can drill a quarter-inch hole and use an end mill, how many can micromachine? Based on my experience, I estimate about 10%. There’s huge opportunity out there.

I understand that most facilities have standard machines, so they can handle an array of different work; but that doesn’t mean adding micromachining capabilities requires capital investment. With the right gear and know-how, standard machines can micromachine successfully.

What Micromachining Is And Is Not

Before we dig into tooling, machines, and other key micromachining factors, let’s establish what micromachining is: not necessarily a high-speed operation in relation to chip load per tooth, but producing a very small amount of chips with each tool path. Think of it as a high spindle speed relative to the cutter diameter. It’s not limited to miniature parts; the part may be large, but its details may require ultrasmall profiles that can be achieved only by micromachining.

Tooling suppliers see the opportunities in micromachining, too, and more and more are fighting for market share. But beware. Micro tools are incredibly difficult to produce, and newer manufacturers are still learning how. You need to do your homework – for example, are they sourcing tools from the same grade of material and/or using a third party? – to understand what it takes to make these tools and trust your source.

Tool carbide should be ultrafine grain (nano or submicron grain size) to ensure high abrasion resistance and toughness. While coatings are valuable, they can negatively impact performance. Micromachining tools have extremely fine surface finishes and sharp cutting edges. Coatings can fill in valuable space — a flute on a drill, for example — needed for proper chip evacuation, which is critical in micromachining applications.

We consider any tool with a diameter of less than 3 mm to be a micro tool. As you tool up a standard machine, however, remember that micro tools aren’t smaller versions of standard tools. Many features of a macro tool can’t be adapted to micro sizes.

As one quick example, Sphinx manufactures a deep-hole micro drill that’s less than 1.5 mm in diameter and runs 80 x D. We only add flutes at the tip because pecking in 1-2 x D increments is required and it’s best to leave the remainder of the drill cylindrical for added strength. (We always recommend using the shortest tool possible to avoid deflection.)

Also, what’s considered very sharp for a standard tool — say, 10 microns — isn’t for a micro tool. A 10-micron cutting edge radii taking a three-micron chip load isn’t just dull; it’s a highly negative rake. Because of their relatively dull edges, the energy required for micro cutters relative to the minimum mandatory requirements can be up to 10 times higher than their larger version (more on this a little later).

What’s more, because the chips micro tools generate are smaller, less heat is transferred to them, resulting in less displacement from the tool and cut. This creates a tendency for cut material to adhere to the tool. To avoid built-up edges, the operator should increase speed as long as cutting performance remains stable and use coolant to keep the work clean. Make sure whatever combination of coolant and air you use isn’t too aggressive for such delicate work.

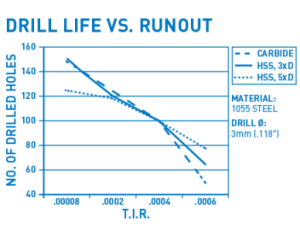

Speaking of delicate, the slightest bit of runout is often responsible for most problems associated with high-RPM micromachining. A cutting tool with a 0.010-inch diameter taking a chip load of less than one-tenth per tooth must be managed to better than one-tenth runout accuracy. ER systems aren’t accurate enough for this kind of application.

When runout occurs, the edge most affected takes over most of the cutting. The uneven wear leads to tool failure much quicker than if the tool rotates about the centerline as intended.

In one customer application, drilling 0.590 inches into a steel workpiece with a 0.118-inch-diameter carbide drill and a holder with 0.00008-inch runout accuracy produced 2,300 holes. A holder with 0.0006-inch runout accuracy was only able to produce 800 holes. The shop could save hundreds of dollars a month in carbide costs as well as labor costs due to less tool changing by using a different toolholder.

Powering an Existing Machine for Micromachining

Which brings us to the elephant in the room: how to generate the power and speed needed on a standard machine to enable micromachining tools to perform well.

Maxing out an existing machine tool is an option, but you’ll want to establish a baseline. Is the spindle perpendicular and without damage that could transfer to the tool? Is the servo control fine enough for micro work? Also, know your torque. When output speed increases, available torque decreases. As you approach the upper limits of speed, horsepower at the cut can sink. Do not exceed recommended torque or force deeper cuts.

There are a handful of reasons maxing out a machine isn’t always a good idea, especially for extended periods. More speed leads to more friction and heat in the machine, which can cause thermal expansion that deteriorates bearings and gears and elongates the Z-axis. And another point about runout: Spindle measurements are usually done at low RPMs when dynamic runout at maximum speed can be 10x to 20x higher.

That brings us to our best recommendation for boosting machine speed: spindle speeders. There are three types: gear-driven that reach about 24,000 RPM; electric-driven that max out around 80,000 RPM; and air-powered, which are faster yet (for example, our RBX12 spindle speeder can reach 120,000 RPM).

In addition to the benefit of speed, a spindle speeder saves wear and tear because the machine tool’s spindle doesn’t turn. The lack of heat buildup allows air spindles to run the long cutting cycles common in micromachining. There are also significant cost savings to exhausting air pressure into the atmosphere as opposed to driving the spindle with a motor.

Knowing the importance of runout, we integrate micro collets into our speeders that are capable of extreme clamping forces down to diameters of 0.018-inch clamping intervals of 0.004 inches. This minimal amount of collapsibility ensures consistent mating of the collet bore against the cutting tool shank and provides excellent gripping force and low runout.

Don’t Learn the Hard Way

I’m reminded of a customer who bought a new 60,000-RPM machine, cut out the floor, added special padding in a humidity- and temperature-controlled room, and identified the 0.006-inch-diameter tools. However, my calculations showed the spindle needed to reach 127,000 RPM to achieve the feed rate required for the job. This huge investment wasn’t going to deliver the performance the customer needed. We added a 150,000-RPM air-power spindle (I can’t think of many scenarios where rotating too fast is an issue).

The customer was able to perform the job as anticipated, but the spindle speeder was just one reason for success. It wasn’t without the right cutters, the right collet, measuring and remeasuring runout. We dotted the I’s and crossed the T’s, taking the time to get it right.

Using a conventional machine to micromachine isn’t going to be rainbows and unicorns. But I ask again: What makes your shop different? What value do you add that sets you apart from every other shop with 40/20, CAT 40 vertical machines? How many jobs have you no-quoted because you couldn’t micromachine?

There are few opportunities to affordably expand your menu of offerings than to start micromachining with the help of the right tools and a spindle speeder. So pull your best machinist aside, consider a presetter to help with runout accuracies, and carve out a new revenue stream.

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.