What’s the Difference Between ER Nuts?

Few would argue with calling the ER style the world’s default collet chuck holder system across the world. It’s an open standard anyone can make. When it comes to dialing in an ER system’s performance to match a specific application’s requirements and/or long life, there are three components to consider: the collet, the body of the holder and the nut.

ER collets from BIG KAISER work with any other holder, are made to ISO and DIN standards, and are made in-house—no private labeling—to BIG DAISHOWA’s exacting tolerances. The bodies of our holders have an extended bore designed specifically to improve runout accuracy and help to achieve our guarantee of 1-micron runout at 4xD when used with other BIG DAISHOWA components.

When it comes to nuts, there are choices aside from the standard ER nut—our ERN is interchangeable with any other holder brand, but accuracy cannot be guaranteed. Let’s look at the other options.

When it comes to nuts, there are choices aside from the standard ER nut—our ERN is interchangeable with any other holder brand, but accuracy cannot be guaranteed. Let’s look at the other options.

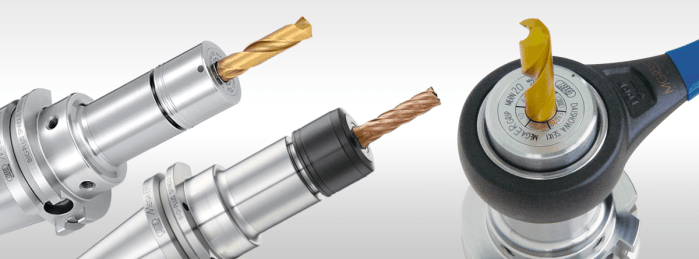

Mega ER Solid Nut – This is a one-piece, solid steel nut without bearings. This nut has a counterbore on the back to match the pilot, so that when this nut goes on the holder body, it’s sealed from the backside as well.

Flats are also removed from the nut; it’s fully round. The nut design also allows for use of our MEGA Wrench for even 360-degree clamping. When compared to wrenches that are only a foot long and flat bar stock, the MEGA Wrench, with its rubber handle, makes tightening easier.

Mega ER Nut – This high-performance bearing type nut, effectively sets the standard. It’s shaped exactly the same as the solid nut but includes a bearing raceway. This reduces the required tightening torque by about 40 percent, lessening wear and operator stress.

As opposed to a solid nut where its face slides along the top of the collet, causing wear, the collet is free to rotate without the nut, and bearings reduce wear caused by the sliding motion. Reduced clamping torque protects the threads of the holder too. Sure, threads are going to slide against each other, but this nut can cut that wear in half.

When compared side-by-side to a solid after 500 clamping cycles, the MEGA ER maintains about 50 percent more gripping strength with a 30 percent reduction in runout.

MEGA Perfect Seal – This nut has all the features of the bearing-type nut but adds a front O-ring to seal for coolant-through delivery up to 1,500 PSI direct to the end of the cutting tool. Alternatively, the O-ring can be moved for jet coolant mode where coolant is delivered closer to the cutting shank, which is ideal for finishing jobs.

For the best performance we recommend all three of our components, because we know they are held to similar standards and tolerances. If you’re looking to improve performance on an existing tool, replacing both the collet and nut will provide the most improvement. But if you must choose, the nut will make the most impact.

Interestingly, we’ve had the most success with customers that aren’t using all three together, for example on transfer lines, where the ER collet chuck is built into the spindle of a dedicated machine. While you may not be able to replace the holder, even if it’s another brand, you can still improve runout with a better nut and/or collet.

Learn more about our entire ER program, arguably the most accurate in the world, click here.

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.