6 Ways to Keep Workholding Chucks in Good Condition

Workholding plays a critical role in the metalworking equipment equation. The spindle, tool holder and program can be perfect, but if the part is not secure, any range of errors can result. Workholding chuck condition is becoming even more important in multi-axis machining where additional angles and motion can amplify problems.

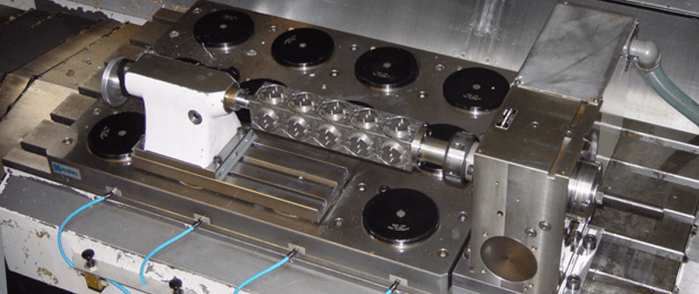

BIG KAISER’s zero-point UNILOCK chucks are ideal for 5-axis and 5-sided machining. The modular system makes part transfers fast, while improving access to the part. These simple and affordable accessories help ensure you can take full advantage of UNILOCK’s capabilities by keeping chucks in clean working condition.

1. Fitting plugs protect the opening of push-to-connect fittings, keeping them clean when other chucks are being used during machining.

2. Flat-face sealed fittings seal when they are disconnected to eliminate contamination.

3. Air blast chucks allow for good location repeatability by cleaning the knob with a blast of air through the center of the chuck as it enters.

4. If a fixture spans multiple chucks, but does not require a knob, chip knobs can be used to protect the locating taper.

5. Chip guards, also known as dust covers, protect the top face of the chuck and locating taper from damage caused by chip wash or impact.

6. An Air filter/regulator/oiler assembly, also called an air prep assembly, regulates the pressure used to operate the chucks while also applying oil to the air, helping to keep chucks lubricated and O-rings in good condition. This add-on also cleans the air used to control the chucks, reducing the wear and tear dirty air can cause over the course of many part exchanges.

When it comes to workholding, don’t just set it and forget it. Keep your UNILOCK chucks clean in order to maximize your long- and short-term return on investment. Learn more about the sizes and options available for these accessories and others here.

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.