After Careful Planning, Machine Shop Adds Presetter to Its Lineup

Celebrating its 30th anniversary this year, Peterson Machining of Boulder, CO, can attribute much of its success to careful planning when it comes time to invest in capital equipment. A recent article in Manufacturing Engineering details the company’s latest investment.

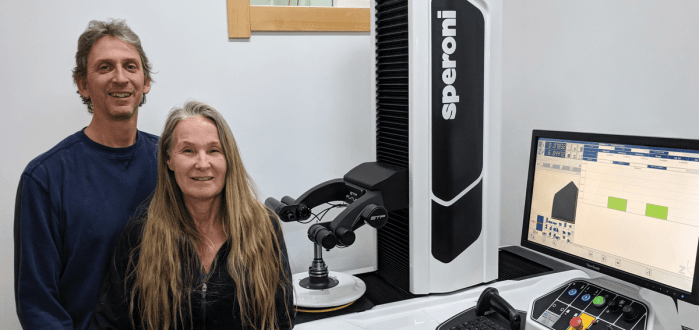

After researching presetters for eight years—including four trips to IMTS—CEO Ronda Peterson knew it was the time to invest in the next level of efficiency for her shop. She knew exactly what she needed—a well-built, durable measuring system that could help manage runout and wear of the micro end mills the shop uses; one that could model tools and be used with verification software to optimize the shop’s five-axis machinery and lights-out operations; and one that could move setup adjustments offline. The Speroni FUTURA STP 66 fit the list of requirements.

While Peterson Machining is capable of high-production work, much of what comes through the shop is prototyping and small batch runs—anywhere from one to 500 units. Some of the more challenging processes involve using micro end mills as small as 0.010″ (0.254 mm) in diameter.

“We create parts in some of our machines that you only know the end mill broke because you can see the engraving didn’t go well,” Peterson said. “The two-camera [high-frequency, sub-pixel, 45X standard optical magnification] ability has been a really big factor in that work.”

The FUTURA is built with Heidenhain scales, Schneeberger guideways, and a rotating spindle that offers 1 μm concentricity and TIR at 300 mm of less than 5 μm. Setups have become so accurate and reliable that shop has been able to set tools and use them throughout the shop, in different machines and operations. This is especially useful in a lot of the aluminum work that Peterson Machining does, since it imposes less wear on the cutters.

The precision and capability of the FUTURA has already proven critical, and with one eye always on the future, Peterson trusts that the pearlitic class 40 cast iron build of the presetter will pay off too. “We like the construction of the machine because longevity is important to us,” said Steve Carper, lead machinist at Peterson Machining. “Since we buy high-end machine tools that we plan to last 20 years, we needed something really solid that would last as long as the machines.”

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.