Use Guide Pins to Assist in Loading of Fixtures to Protect Your Investment

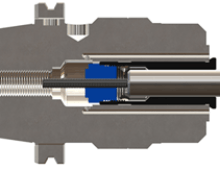

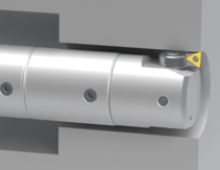

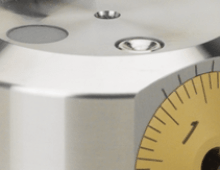

The concept of using guide pins to load large fixtures has been around for a long time, and it even applies when incorporating Unilock zero-point clamping systems in your fixturing. The main Unilock clamping knob is very robust, i.e.: very hard, and as such it can cause damage to a Unilock chuck if a fixture is very heavy or large. Guide pins are set up on the base, and their corresponding holes or notches located on the edge of the fixture pre-position the fixture so, that as it is being lowered, the knobs do not impact the critical location faces of the clamping chuck. This also has the added benefit of keeping operators in a safe location not having to use their hands & fingers to fine-adjust a slightly out-of-place fixture being lowered.

|

|

| Guide pins installed on a sub-plate. | |

|

|

| Corresponding guide holes/notches on fixture plate. | |

|

|

| Fixture plate being lowered on to sub-plate. | |

|

|

| Guide pins and guide notches aid to perfectly align the fixture and sub-plate. | |

By John Zaya

BIG KAISER—Americas

Product Manager – Workholding

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.