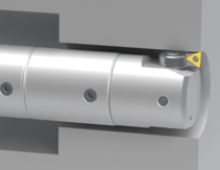

Use Clamp Confirmation to Safely Load and Unload Your Unilock System

Clamp confirmation for any system, UNILOCK or otherwise, is a sound design criterion when building any workholding system. It is very common to see clamp/un-clamp confirmation in many automated loading systems as safety interlocking of the CNC machine, robot, robot EOA (end-of-arm) tooling, and workholding can all be integrated to a single master control.

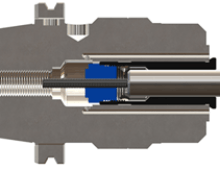

Un-clamp confirmation does have a place in manual situations as well, mostly in large part processing, where cranes are used to lift parts off. When a clamping system is not directly visible underneath a large part, then this requires an external indicator confirming that the system has successfully un-clamped and that it is safe to lift. The indicators and sensors can be pneumatic switches which are offered by BIG KAISER or electrical proximity switches as offered by many other companies.

By John Zaya

BIG KAISER—Americas

Product Manager – Workholding

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.