How the Right Offline Tool Presetter Affects a Shop

The old saying “it won’t make chips – not worth it” doesn’t apply anymore. Considering the accelerating pace of change in technology and the relentless competition your shop faces, how can you possibly afford not to use a presetter?

We hear it all the time when discussing presetters with shops: “It doesn’t make chips – not worth it.” It’s an understandable gut reaction, but in this day and age when a variety of presetters is available at an array of price points, we suggest that folks don’t dismiss the idea from the jump. Selecting the right one for the work you do now – and plan to do down the road – ensures that your investment is paid back, and more quickly.

Let’s first look at a few ways the right presetter can improve a shop, then review some pointers for making sure that you invest in the right one. The benefits of using a presetter include:

Improve the team. Some shops hold the misconception that a tool presetter is the first step towards robots taking over and everyone on the floor losing their jobs. This is simply not true. In fact, most operators and setup specialists that have used presetters wouldn’t know what to do without them; the systems make them more efficient and make their job easier. Additionally, one shift will be able to come in and pick up right where the last shift left off. In the event someone is out because of illness, vacation or if they leave the company, production will face minimal interruption because the team will never be stumped due to nobody knowing the trick that “Herb” picked up 20 years ago.

Spindles stay spinning. I cringe when I hear someone claim that machine tools with built-in probes, touch off devices and lasers are efficiency boosters. They fit squarely inside the “bells and whistles” category. They are slower than presetters and, more importantly, when most of these devices are at work your machine tool isn’t making you money.

More accurate setups the first time/reduced scrap. In-machine measurement tools often fail to measure runout and/or length, scenarios that will still require test cuts. A presetter can measure both a length and diameter (or wear factor) for entry into the machining center’s tool list and can allow the operator to correct runout before a tool goes into production. This typically creates a good part on the first try – dramatically reducing scrap costs. Presetters are better at measuring than machine tools, and machine tools are better at machining than measuring. Period.

Mobilize the tool room. Most tool presetters are made for the floor environment. Affordable carts make it easy to maneuver the system around the shop as setups pop up throughout a day. Another method many shops use is to have the presetter situated in the middle of machining center cells so that the operators can easily and quickly set tools while production continues nearby.

You’ll be able to reinvest savings faster than you think, even with just one machining center. For the sake of simplicity, let’s say someone has a one-machine home shop and spends an hour each day setting tools on the machine. They do six hours of actual cutting per day and value their spindle time at $125 per hour. While one job is running, they can be setting up the next job and reduce changeover to five minutes or less. Even with this little “mom and pop” operation, the most basic presetting machine will provide full return on investment (ROI) in less than a year, and that doesn’t even factor in consumables savings. Most of you reading this probably aren’t working out of your garage, so we’ve made a handy tool available on our website for calculating how fast a presetter will pay you back in more complex scenarios (see Figure 1). Try it out by clicking here.

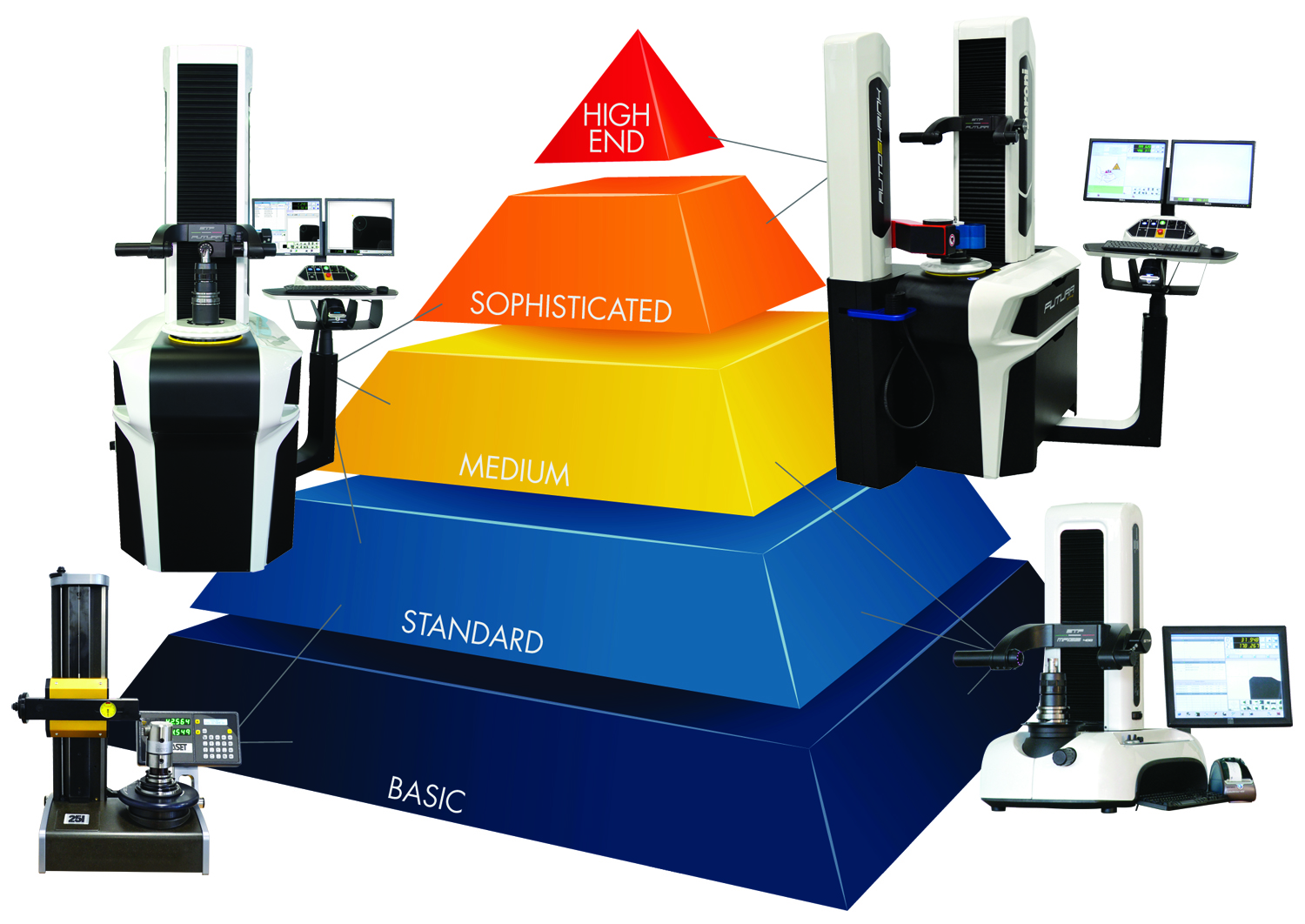

Establish needs vs. wants. Presetters range in price from a few thousand dollars to upwards of $50,000, making it imperative that you select a presetter that suits your needs first and not just what you want. Otherwise, you’ll end up paying for features that you won’t use, meaning you won’t realize ROI until much later than necessary. Don’t let a slick salesperson talk you into “stepping up to the next level.” Instead, find a distributor or supplier that takes the time to understand your operation and makes you aware of the options that may benefit your shop, not just the ones that are trying to make themselves more money.

Honestly consider the features that significantly impact price. Do you really need camera functionality, or is an indicator read-out sufficient? What’s better for your operators: manual or CNC movement? Do you often need to reference data quickly, or can you store it away? How accurate and repeatable do you need your measurements to be? Are you measuring large diameters/lengths, and/or are you measuring accuracy of less than 0.0003 in or cutters with sub-0.01 in diameters? If you’re measuring 100 tools a day, it will be hard to avoid a higher-end presetter. The good news is this: if you can bear the initial investment, you’ll enjoy bigger, faster returns.

Think about today and five years from today. Considering the ever-accelerating pace of change in technology and the relentless competition your shop faces, the work you do today may be different from what you do down the line. Luckily, quality presetters produced by specialized manufacturers, last a long time with minimal service. Quality presetters are essentially future-proof. Those many options mentioned earlier can often be added on later. So if you know you have a certain type of work coming in the future, but don’t need all the functionality that it requires today, you can save a few bucks by buying a system that can grow with you and spread out the cost.

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.