Tooling Advancements Ease Stress for Management

In a recent Advanced Manufacturing Now podcast, Paul Lewis, regional manager for BIG KAISER, sat down with Alan Rooks, editor in chief of Manufacturing Engineering magazine, to discuss changes in recent years that have affected middle management at manufacturing companies.

One such issue is that the speed of information has more than doubled in recent years, necessitating the demand for manufacturers to react quickly to their customers’ needs, yet there are less people involved in the overall manufacturing process.

In addition to assuming more responsibilities for the manufacturing process, middle management has also been tasked with helping the business succeed. Middle managers not only have to answer to customers, but they also must manage the mandates issued by upper management and human resources. “The industry is asking a lot from those people who are responsible for components getting out in a timely, high quality and proficient manner,” Lewis says.

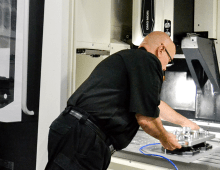

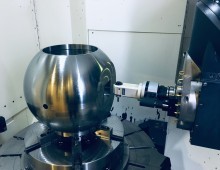

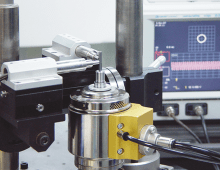

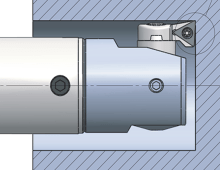

To help combat the increased stress at work, an investment in high-caliber tooling can prevent unexpected things that happen on the manufacturing floor. “Tooling is the lifeblood of making the component. The machine is the body,” Lewis says. “Poor tooling affects quality of components which slows down time on machine.”

Tool holders with a higher accuracy decrease a shop’s expendable costs by fighting tooling situations in which tool wear, tool runout or finish issues are struggles.

To learn more on how premium tooling and future technologies can help alleviate middle management’s struggles, listen to the full podcast.

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.