Comparing Tool Holder Performance and Price

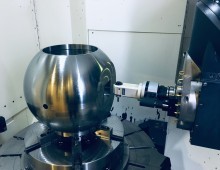

Not all tool holders are created equal, which can present challenges for metalworking professionals. That said, choosing the right one for the right work is clearly of critical importance to successful metalworking performances. For example, if rough milling in a tough alloy is the job, a side lock end mill holder is a sound choice in order to prevent pullout. On the other hand, if saving setup time is key to delivering on a job efficiently, a quick-locking hydraulic chuck may be better.

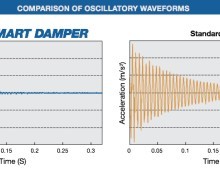

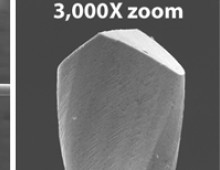

To assist with your tool holder selection we’ve developed this quick-reference guide comparing the most important performance characteristics of different holder types: runout, gripping strength, pullout security, speed, vibration damping and handling.

Price is always a factor too, of course. So, we had our engineers evaluate overall performance of the different holder types—side lock end mill holders, shrink fit holders, collet chucks, milling chucks and hydraulic chucks—as it relates to their typical costs. The assessments you’ll see reflect the holder types and performance in general, not just BIG KAISER products. Check out the guide below, or contact our experts to help select the best tool holder for your needs.

To assist with your tool holder selection, we’ve developed this quick video comparing the five most common holder types: side-lock end mill holders, shrink-fit holders, collet chucks, milling chucks and hydraulic chucks. BIG DAISHOWA engineers have broken down important performance characteristics, including runout, gripping strength, pullout security, speed, vibration damping and handling.

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.