Desmitificando la Selección del Radio de Nariz del Inserto

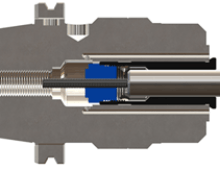

Incluso entre los maquinistas experimentados, elegir el inserto adecuado para taladrar un agujero sigue siendo un proceso difícil lleno de mitos y conceptos erróneos. Sin embargo, no es un mito que la selección del inserto pueda salvar o arruinar completamente el rendimiento en una aplicación. Podemos pasar todo el día hablando sobre el mejor sustrato/revestimiento del inserto (o su ausencia), forma, geometría del rompevirutas, etc., para un trabajo, pero considero importante abordar uno de los problemas más comunes que encuentro: el uso de un radio de nariz de inserto inadecuado.

He hablado con maquinistas que son leales a un tamaño de radio de nariz específico o que dejan cierta cantidad de material en un agujero simplemente porque funcionó en un trabajo hace años y parece funcionar bien en la mayoría de los otros trabajos. Luego se sorprenden al trabajar en un nuevo proyecto y de repente aparece un fuerte vibrado o un mal acabado superficial. La verdad es que la selección adecuada del radio de nariz depende de las especificaciones únicas de cada trabajo, principalmente:

- Cuánto material queda de stock

- Velocidad de avance deseada o acabado superficial

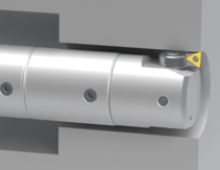

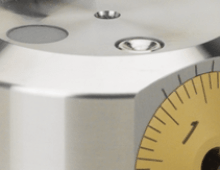

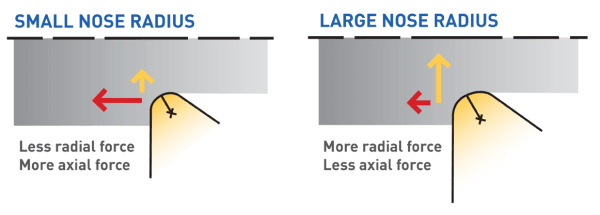

En general, se desea minimizar las fuerzas radiales y maximizar las fuerzas axiales que actúan sobre el filo de corte. El temido fenómeno de vibrado se produce por exceso de fuerza radial que desvía la herramienta, haciendo que "rebote" rápidamente sobre la pared del agujero. La regla general típica es tener una profundidad de corte radial de la mitad a dos tercios del radio de la nariz. Por ejemplo, al usar un inserto con radio de nariz de 16 milésimas, deje un stock de 16-20 milésimas en diámetro para la pasada de acabado (tenga cuidado de no confundir profundidad de corte radial con profundidad de corte en diámetro). Mantener estas fuerzas de corte adecuadas favorece la buena formación de viruta. Intente usar un radio de nariz más pequeño a medida que los trabajos de taladrado se prolongan, ya que esto combatirá las fuerzas radiales excesivas que causan vibrado. Pero sobre todo, asegúrese de dejar la cantidad correcta de material para sus insertos particulares.

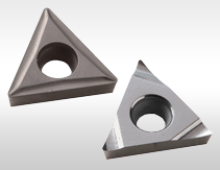

A veces, los trabajos requerirán un acabado superficial específico. El acabado superficial, el radio de nariz del inserto y la velocidad de avance van de la mano. Sin entrar en demasiados detalles técnicos, el acabado superficial mejora al disminuir la velocidad de avance (manteniendo constante la velocidad de giro) y al aumentar el tamaño del radio de nariz. Estas son las dos primeras opciones que querrá considerar. Por esta razón, no olvide aumentar la cantidad de stock si cambia a un radio de nariz más grande. Además, disminuir demasiado la velocidad de avance en un intento de obtener un mejor acabado superficial corre el riesgo de producir vibrado, porque la profundidad axial de corte es menor que el reborde del inserto. Si todo lo demás falla, puede "hacer trampa" cambiando la forma del radio de nariz a una geometría tipo wiper. Esto hace que el filo de corte radial sea efectivamente plano, produciendo un acabado superficial 2 veces mejor que un radio de nariz estándar al mismo avance.

Otro factor a tener en cuenta es que una esquina con radio de nariz más pequeño será más propensa a romperse que un inserto del mismo tamaño con un radio de nariz más grande.

Como puede ver, hay muchos factores en juego y es fácil que la cabeza comience a dar vueltas. Esperemos que algunos de estos consejos lo orienten en la dirección correcta. Si las aplicaciones difíciles no responden a nada de lo que haga, o si necesita ayuda para seleccionar el inserto adecuado, el departamento técnico de BIG DAISHOWA está aquí para asistirlo. Por favor, contáctenos en engineering@us.bigdaishowa.com o al (224) 770-2999 para obtener ayuda con insertos o cualquier otra pregunta sobre herramientas.

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.

Añadir nuevo comentario