Tool Holder Balance – New ISO 16084 Standard is Here

Vice president of sales and engineering, Jack Burley, once again took to the pages of Fabricating & Metalworking magazine to share some valuable information on a new standard for balancing tools and tool systems that apply to all of today’s relevant variables for safe and productive machining. This standard is known as the ISO 16084.

For decades now, ISO 1940-1 has been the standard that tooling manufacturers, machine builders and metalworking operations have used. To put it into perspective, the “1940” in the standard’s name is the year it was approved. Due to today’s advanced manufacturing environment, it was necessary to modernize this standard.

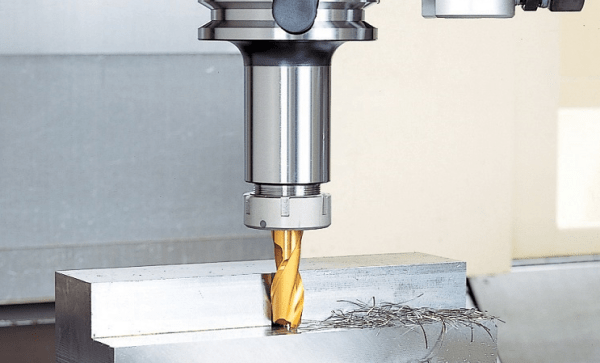

Jack writes, “Back then, the most advanced machines would have spun larger, heavier tools at a max speed of about 4,000 rpm. If you tried to apply the math from those days to today, you’d get impossible, literally unachievable, values. In this day and age, the fairly arbitrary G2.5 balance specification is no longer practical, technically possible or economically feasible.”

Along with providing information on how the ISO 1940-1 has supported manufacturers, Jack lists a few ways that this updated ISO 16084 standard is different:

- There is accounting for the dynamic load ratings of spindle bearings of common sizes of tool connections.

- It factors in radial runout of most tool connections, including HSK, steep taper or polygon.

- An option is provided for standard balancing or fine balancing, depending on the machining conditions, such as roughing or finishing.

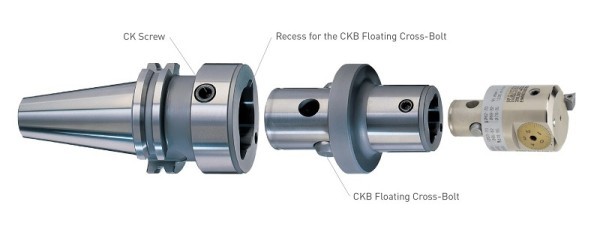

- There is a basis for balancing components of modular tools with multiple parts.

“This standard is more difficult to understand because of the many complex variables included in the calculations,” says Jack. “However, balancing tools to this standard will be more practical, both technically and economically.”

The new ISO 16084 standard includes balancing factors of tool systems with up to six components, such as modular assemblies like the BIG KAISER 310 Series fine boring tool. Application data and cutting tool type are included in the standard.

To fully understand the difference between ISO 1940-1 and the new draft standard ISO 16084, click here to read Jack’s full article.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.