Microsurgery Drives Micromachining from Low-vibe to Practically No-vibe

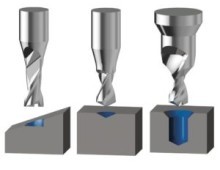

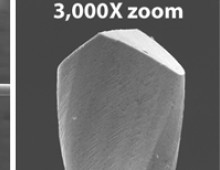

The Micro Tricut drill reamer features a diameter range of Ø.20mm-2.99mm at 5xD, and provides a hole tolerance of H7.

As surgeries become less invasive, surgical instruments and tools are shrinking and tool manufacturers are asked to constantly improve the precision and tolerances of the micromachining process. The ultimate goal is stability – near-zero vibration, near-zero runout.

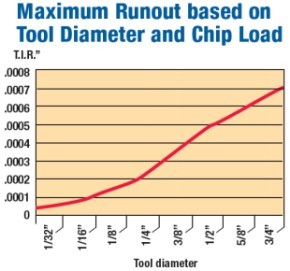

And as Jack Burley, VP Sales & Engineering, explained to SME last year, the smaller the drilling diameter, the more significant runout becomes. Recommended runout levels are tiny, with a maximum of less than .0001” (.0025mm) total indicated runout (TIR, or the distance between the largest positive direction and the largest negative direction) measured at four times diameter.

Microdrills and runout don’t mix. The above chart shows the constant relationship between tool diameter and runout as a function of chip load of the cutting tool.

Microdrilling tools for the medical industry exemplify precision – already tight tolerances are exacerbated by the minute sizes. BIG Kaiser offers products well within the industry-accepted micro-range, beginning at diameters of .002” (.05mm), in increments of .01mm (0.0004”). Our Spirec Micro Drills from Sphinx, for instance, are high speed tools for drilling in the smallest diameter range. Sphinx offers these drills in both High Speed Steel (.05mm-3.175mm) and Solid Carbide (.05mm-2.0mm in increments of .01mm).

Microdrilling Tips

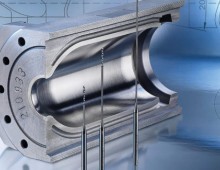

With tiny tolerances, don’t settle for shrink fit. A lot of users mistakenly consider shrink fit technology to be the most reliable method to ensure acceptable runout, but BIG Kaiser research indicates otherwise. Since we recommend inspecting for TIR each time a tool is changed when microdrilling, precision collets manufactured to class AA, like our New Baby and ERC collets from BIG Daishowa Seiki, can provide stable runout and a higher ease of tool changeout or adjustment.

How will you hold the microtool? In microdrilling the concentricity between the shank, drill point, and margins of the tool must be held to near-perfect tolerances. We find that many users choose to hold drills with common shank dimensions (i.e. 2mm shank and drill diameter), also known as a “wire” approach. In this case, it is best to grind the drill to ensure runout is low and very stable. Although the wire drill approach features a lower relative manufacturing cost, it requires a wider range of tool holder clamping sizes to accommodate different diameter drills. This is much more affordable in a collet system (1 body/nut and multiple collets) vs. a shrink fit system (multiple bodies).

Burley offers some additional questions to think about when microdrilling in this Production Machining article.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.