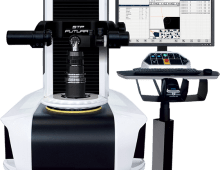

A Guide to Why Your Shop Should Invest in a Tool Presetter, and Choosing the Right One

The right presetter can improve a shop’s performance in ways that are impossible to ignore. The trick, according to a March article in Fabricating & Metalworking magazine by BIG KAISER’s Doug Sumner? Finding the right one for the work you need—because making the right decision will ensure that your investment is paid back. Fast.

The reasons for investing in a tool presetter are endless. Our first-time tool presetter customers always tell us they don’t understand how they ever got along without one. Anyone in the shop can be trained and trusted to use it and setups will be consistent from shift to shift. Then factor in the downtime where your “tool setup guy” has his head and body in the machine performing offset tricks he learned 20 years ago, all the while the machine is sitting idle…with a spindle value of how much per hour!?

OK, so your shop is a little more advanced, and you have built in probes and touch-off devices inside your machining center. Good for you, that’s a step in the right direction. But guess what? Your spindle is still not making chips during those ops and that is COSTING YOU MONEY!

We’ve got a handy tool available on our website to help put this in perspective. Try out our Presetter Payback Calculator here.

So now you’ve convinced yourself that you do indeed need, not want, a tool presetter. What do you do next? The logical step would be to read our article and dive deep with us into factors such as:

- Establishing needs vs wants

- Consider the features that significantly impact price

- Think about today and five years from today

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.