Connectivity Expands Presetter’s Reach Beyond Tool Measurement

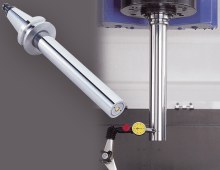

A presetter on the shop floor provides the opportunity to improve setup efficiencies. By moving setup time from the machine to offline, spindles can stay spinning, tools last longer, cuts are done right the first time and the chances of human error are dramatically reduced. Even the most basic benchtop, readout-based presetter can make these things happen.

Presetters have evolved. There are now powerful PC-based, touchscreen controls that can connect to other important components and systems across an entire metalworking business. This connectivity allows for the fast accurate exchange of data from place to place, person to person and machine to machine. Here are a few examples of how an integrated presetter can lay the foundation for smart manufacturing.

Programming software. You can import/export, catalog and program all your tools within seconds online. The seamless transfer of existing CAM tool data to a control, using software like Edge 2.0 or Edge Pro, eliminates the tool data entry process at the presetter.

Simulation software. Especially valuable in multi-axis machining, presetters allow for the export of 3D scan profiles to a simulation software like VERICUT.

Printers. On the more rudimentary side of CNC controls, label makers can help bridge a wireless connectivity gap. A label maker connected to a presetter can print out a bar code or QR code that stays with the tool. If you need a hard copy report or tool lists, a standard office printer can connect.

Scanning devices. On the other side of the bridge, it’s easier for handheld scanners to connect wirelessly to a presetter and/or machine control. These handheld devices are used to read any labels, gather information like offsets and transfer them. Our SPI – Simple Post Interface -- can be configured several different ways, including with a single scanner to instantly transfer offsets to multiple machines.

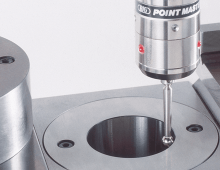

The tool itself. The best way to safeguard tool data is to keep it with the tool. Radio frequency identification (RFID) is an effective way to do this. Once all the offsets are measured, a presetter can write all the dimensions to the tag that’s embedded in the holder. An equipped machine can then read the tag and updated its offset table. The data will be retained even if the tool is put in the wrong machine.

Tool storage. An electronically controlled tool storage station can be synched with a presetter for more detailed inventory. Building a tool library into the presetter reduces redundancy, manages stock and reduces tooling costs. This eases inventory management, as the system keeps close track of what tooling is needed for each job, what is available in the shop and what needs to be ordered.

Cell controllers. When direct connection is possible, there are software options that allow for direct integration of the presetter with the controller database. This allows for real-time offset transfers.

Remote support. The PC-based presetters we’re talking about can even make troubleshooting easier with the help of connectivity. Equipped controls can connect directly with experts on the system for fast solutions.

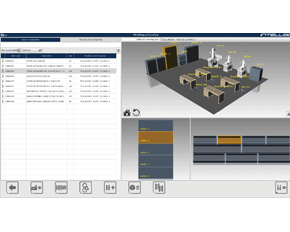

Essentially everything. A comprehensive tool management system like our Intelligo can turn a presetter into the data hub of the shop. Components, assemblies, jobs, kits and inventory levels can all be traced from the moment they land on the floor, eliminating redundancies. This unlocks powerful data that allows for proactive purchasing and job planning. It’s also a way to track tool wear or performance on certain jobs and identify any inefficiencies.

Combining postprocessing and tool management, Intelligo can even smooth the transition from one job to another by finding common tools and locating the remaining tools needed, whether they’re in a machine, the tool crib or disassembled.

A tool presetter can give a shop a jump start on Industry 4.0 without having to reorganize the operation. The more data you have, the better decisions you can make.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.