Preserving Tool Holders and Speeding Lathe Setups with Accessories

We may be known best for our high-performance tooling, but when it comes down to it, we’re all about helping shops improve efficiency throughout their processes. These easy-to-use measuring devices can do just that. Specifically, they can help protect capital machinery, prevent scrapped parts, and speed up setups or programming—just to name few of the benefits.

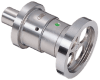

Automatic tool changer (ATC) alignment

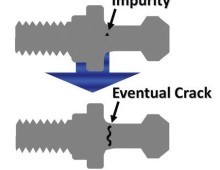

Regular automatic tool changer inspection and measurement is a must. While there’s more between it and the action of the cutting zone than, say, a tool or holder, contamination and wear is still common—and if undiagnosed, can increase runout, shorten tool life or even worse. These precise and repeatable measuring devices help you avoid these problems and maintain performance.

If a machine has an ATC, it’s crucial that the exchange of the holder from the gripper into the spindle is a clean one. If it’s not, runout can result, or even damage the spindle and holder. The ATC Alignment Tool helps validate and maintain proper synchronization of this critical action.

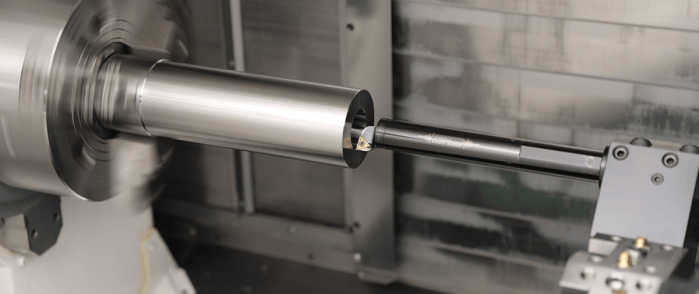

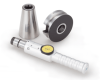

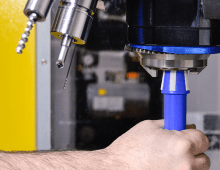

Fast and precision lathe setups

In many cases, we’ve been able to take technology we’ve developed for milling machinery—or to produce our products—and translate them into lathe solutions. One is the Lathe Master, which allows for setup of the cutting edge position for internal, external or facing tools without trial cutting.

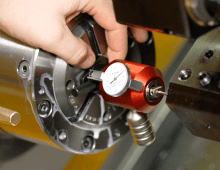

Another is the Centering Tool, which uses a static dial gage for easy reading and adjustments, especially in small lathes.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.