A Vision for Precision

Click here to watch the EWB-UP in action.

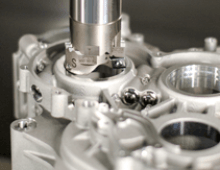

For a company specializing in high-precision modular tooling systems, every step of the development and manufacturing process must be under scrutiny. Up to the task, Heinz Kaiser AG (Rümlang, Switzerland) goes to great lengths to ensure superior performance and repeatability.

Their rigorous inspection process requires every article in production to be serialized for tracking. The actual inspection programs are recorded and filed for at least ten years, so production files for any single tool can be analyzed.

The Kaiser facility itself is structured with defined processes for each machining cell and work station. This environment combines the efficiency of automation with the knowledge of highly-skilled craftsmen. Rooms are even temperature controlled to a degree’s variance so as to guarantee uniformity against heat-related metal expansion and contraction.

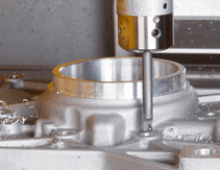

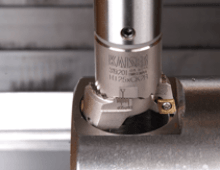

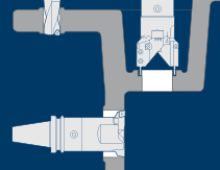

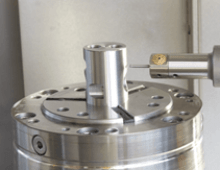

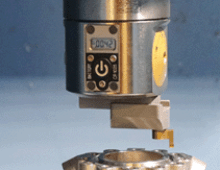

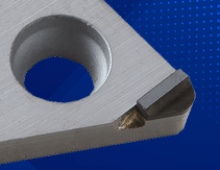

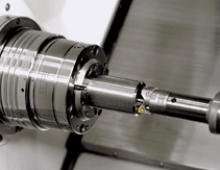

The EWB-UP boring series exemplifies Kaiser’s ability to leverage refined manufacturing processes, engineering knowledge and skilled craftsmanship. The boring tool is the industry’s finest adjusting boring head – and it is not easy to manufacture. The tool is precision ground on a Sunnen cross-honing machine to achieve the tool carrier’s precise bore geometry. This finished component has to hold extreme tolerances in roundness and straightness. These precision-machined parts are then hand-matched to their life-long counterparts, which have been thread ground on a Studer. This manual matching of each spindle to its tool carrier assures near-perfect precision and virtually backlash-free screw threads.

Every Kaiser product is available in both metric and inch systems, with unique part numbers and production runs for each. Most boring tool manufacturers produce only a metric version of their tool, and then convert them for inches by changing the dial face to read in inches. The result is a slight error with every adjustment – a full turn of the dial will come up short every time, at .00195″ instead of .002″. If a true inch and metric head are taken apart and pitches measured and compared, there is only a four-micron difference. This may seem too small to matter, but it represents what sets Kaiser apart from its competitors. Kaiser customers are looking for exactness.

Kaiser’s passion for precision exudes from every facet of the company, including its diverse line of high-precision products, rigorous inspection, precision machining and quality control checks. These high standards for exceptional performance serve as a cornerstone for the company’s ongoing success for over 60 years.

Click here for a video demonstration of the EWB-UP boring tool.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.