Not Your Run-of-the-Mill Tools

Within our comprehensive suite of tooling solutions, we often talk in generalizations about different “buckets,” or tooling categories. But in doing so – discussing cutting tools, for instance – it’s easy to neglect the many truly unique, difficult-to-categorize products that we offer under the “milling” umbrella. Sure, there are other products similar to our recently launched R-Cutter, BF-Cutter, and Speed Finisher from BIG Daishowa, but nobody else is doing it quite like us in terms of design features, precision and productivity.

At first blush, some of these products can appear niche – after all, they don’t look like your standard chamfering tools, back spot-facing tools or face mills. But if you’re of the opinion, as we are, that the right tool for any job is essential, it’s fun to think about the innumerable jobs that specialized tools like these can accomplish, and do so more efficiently than the old standard stand-bys.

A glance at our new BIG Daishowa Indexable Cutting Tools Catalog reveals many of these truly exclusive products. Below are snapshots of three of our newest – in fact, the Speed Finisher is so new that it didn’t even make it into the catalog!

These products rarely get a lot of sunshine, as most people don’t think of us as a cutting tool company, but instead associate us with precision boring tools, tool holders, tool presetters and workholding. So, we’re taking this opportunity to highlight a few of our new cooler and unique indexable cutters.

R-Cutter

The R-Cutter is an ultra high feed front and back radius chamfering mill which features high rake angles that reduce cutting resistance and minimize burr generation. The radius chamfering mill is offered as a single-insert design and a four-insert design for higher feed rates. The coated carbide insert design allows for four indexes, is available with radii of .02”-.16”, and is optimized for all steels (including stainless), cast iron and aluminum.

A variety of R-Cutter types are available, including a single insert front chamfering-only design with shank diameters of Ø16 and Ø20mm, and front-and-back combination chamfering models with cutting shank diameters of Ø10, Ø16 and Ø32mm. Each model featuring a single insert design allows for cutting in the tightest of spaces.

Click here to watch the R-Cutter in action.

BF-Cutter

The BF-Cutter was exclusively designed for back spot facing of cap bolt holes, sizes M6-M16. It features the world’s smallest square indexable insert (with 4 indexes), and is ideal for all steels (including stainless), cast iron and aluminum. The coolant-through capability helps cool down the back side cutting area, increasing tool life – a feature not available in most other models on the market. The BF-Cutter is available for minimum facing diameters beginning at Ø.433” and up to Ø1.024”. A unique, offset design allows for easy programming – simply offset the centers between the machine spindle and the hole when entering or exiting the hole with the cutter. The minimum hole diameter for possible entry is Ø.256”.

Click here to watch the BF-Cutter in action.

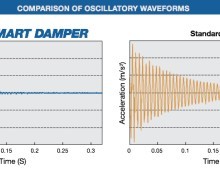

Speed Finisher

Cutting edges on the BIG Daishowa Speed Finisher face mill for aluminum or cast iron are easily adjustable to within 1μm of each other, offering mirror-like finishes through maximum speeds up to 20,000 RPM.

The Speed Finisher allows for this ultra-fast cutting height adjustment through simple construction. After clamping the insert, the finely-pitched lifting screw lifts up the insert directly by revolving the lifting nut from the side. An exclusive presetter is optionally available to further reduce adjustment time and enhance adjustment accuracy.

Click here to watch the Speed Finisher in action.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.