Meet a Foreman with Foresight

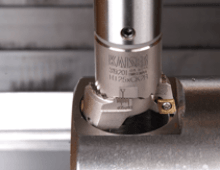

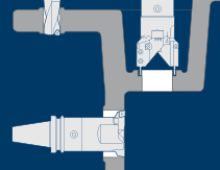

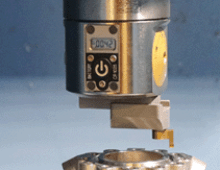

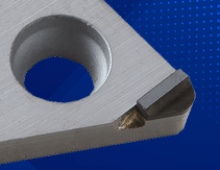

It can be easier to buy the cheaper part, the cheaper consumable, the cheaper tooling and see some savings realized up front. But, the path of least resistance or the quick payback isn’t always best. July’s Cutting Tool Engineering features a BIG Kaiser customer that chose KAISER’s SW series twin cutter rough boring heads with the big picture in mind and is reaping big benefits today.

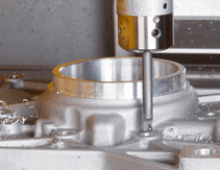

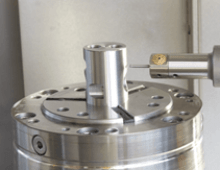

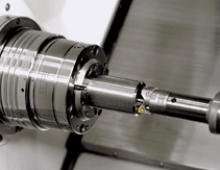

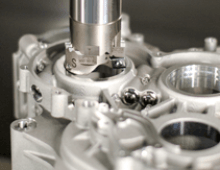

Custom Machining Corp. builds canning machines for some of the largest canning suppliers in the world. The bases of these machines are large, heavy duty blocks of steel that need several bearing pocket bores for mounting the machinery. By swapping out their commodity heads with premium KAISER tooling, they are saving 2.5 hours on every base they produce.

Canning machine base built by Custom Machining Corp with the help of the KAISER 319 SW rough boring head

Sure, the SW series heads are generally a better way to remove the material, but Shop Formean Siggi Sigurdsson had a different kind of payoff in mind when he started exploring the idea of introducing the KAISER twin cutter to his process. “What we could do with the extra time is where my mind went…,” Sigurdsson says in the article.

Because the machine bases aren’t the only part the shop produces, the machine is freed up to do other jobs that before had to wait on the side for the slower, less powerful heads to do the same work.

The story is a great example of how investing in premium BIG Kaiser tooling pays lasting dividends that far outweigh the short-term savings of lower quality equipment. Read the full article, “When the Boring Gets Rough…”, here.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.