Job Shop Eliminates Over 90% of Scrap with BIG KAISER Digital Boring Heads

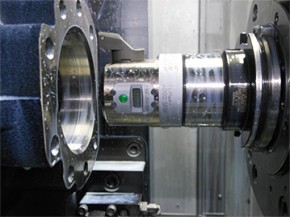

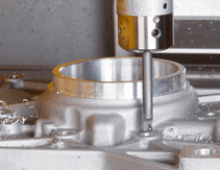

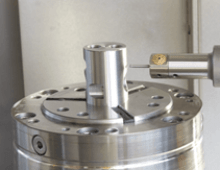

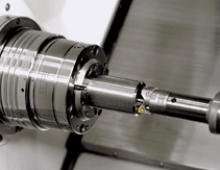

BIG KAISER’s digital precision boring heads, from Swiss partner KAISER were part of a case study alongside Impact CNC in the September issue of Modern Machine Shop. Impact CNC needed a solution to combat its scrap rate of almost 4 percent which was obviously hurting its bottom line.

According to Aaron Schoon, Impact CNC manufacturing engineer, the Columbia City, Indiana shop “knew it was time for a change.”

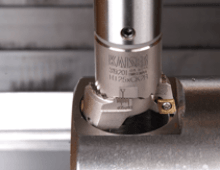

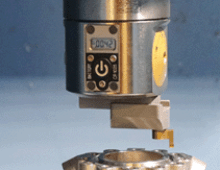

“We tested quite a few boring heads offered on the market—all digital,” Schoon said in the article. “That seemed to be the direction the industry was moving in, so it just made sense to go digital. Operators speak digital these days.”

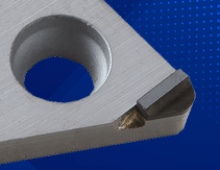

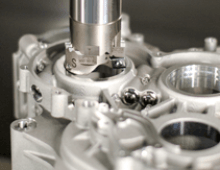

After introducing KAISER digital boring heads, Impact CNC noticed over a 90% reduction in scrap plus improved accuracy. In addition to being digital, the KAISER tools had an overall better design, according to Schoon. The direct-drive screw eliminated backlash – creating a longer lasting product, he said.

Read the entire Modern Machine Shop article, Digital Tooling Improves Accuracy, Reduces Scrap.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.