Boring Heads for the Digital Age

There may have been a time when good enough was good enough, but in today’s competitive metalworking market, good enough won’t cut it. Last summer, for instance, we blogged about how accessories aren’t just luxuries anymore. The same holds true for boring tools – just because your analog boring heads have gotten you this far, that’s no reason to settle.

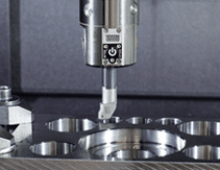

Digital boring tools simply offer a greater deal of precision and consistency – eliminating the need for multiple corrections drives down the setup cost of any application. We’ve talked at length about the easy 1:1 boring head trade off in swapping out exitsing Kaiser boring heads for the new EWD digital models. But maybe an equally important question would be why to make the leap in the first place.

We asked Matt Tegelman, Product Manager – Kaiser, capable hunter and all around nice guy to address not the how or what, but the why in the case for converting to digital.

“Digital boring heads bridge the technology gap between digital part measuring technology and existing analog tooling systems. Today’s machine operators use keypads and computers to run tooling programs, and measure parts with digital gages and CMM’s,” Tegelman says. “A boring tool with a digital readout allows the user an easier way to make sure the first diameter correction is exactly what’s required from the first hole measurement. Kaiser digital boring heads show diametric changes down to .00005” and the measurement system eliminates concerns with dial/cartridge backlash.”

Ease of use alone helps to reduce human error – return on investment in digital boring will differ from shop to shop, but thanks to all of these factors, it’ll be faster than you think. Like your cell phone or computer, it won’t be long until you wonder how you ever lived without a digital interface.

“And most importantly, they are designed for use in real-life manufacturing environments,” Tegelman adds. “This means no further limitations on cutting parameters, coolant delivery, etc. when compared to current products.”

Read more about the IP 69K seal rated (highest possible) Series 112, 310 and 318 digital boring heads.

Click here to see why, when it comes to our boring tools, precision SHOWS.

To begin a discussion with BIG Kaiser about upgrading to digital technology, please submit your information here.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

Add new comment