Proper Clamping of Mechanical Milling Chucks

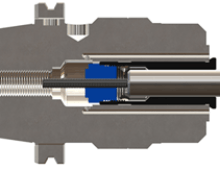

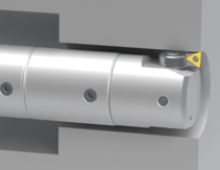

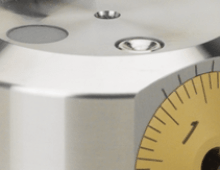

Proper clamping techniques will ensure the proper operation of all mechanical milling chucks. With MEGA Double Power and Hi-Power Slim type chucks it is very important to stop when the nut contacts the main body. If the operator over tightens or “jerks” the wrench after contact is made, the two faces will wring together making it much more difficult to loosen the tool. After the tool is released it is also very important to rotate the nut two additional rotations after the tool can be removed. This makes sure the chuck is fully released and is ready to be clamped again. If the chuck is retightened without fully releasing the nut the gripping strength will be reduced.

By Alan Miller

BIG KAISER—Americas

Engineering Manager & Product Manager — BIG

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.