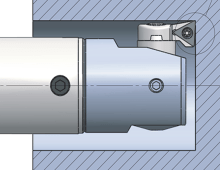

BIG Kaiser Spindle Speeders Highlighted in Micro Manufacturing

Micro Manufacturing’s August issue featured a tech article from one of BIG Kaiser’s very own, Gerard Vacio. Vacio’s article “Up to Speed: Spindle speeders allow micromachining on lower-rpm machines” discusses the enhanced capability of modern CNC machine tools and the full line of hi-tech features included – but how they still have practical limits.

Vacio explains that today’s CNC machines are “being tasked with operating at more than 60,000 rpm to facilitate micromachining with small diameter cutting tools. These speeds bring balance and dynamic runout into play, both of which are difficult to manage when using large toolholders.”

Air turbine spindle speeders are hoping to eradicate this problem since it only needs to rotate a turbine to drive the attached tool holding system. These spindles are small in size and lightweight in comparison to a typical machine spindle, allowing operators to overcome the issues that cause difficulty with high speed micromachining such as dynamic runout and balance issues. As it relates to the tooling – Vacio goes on to explain “the wear life and performance of cutting tools are best when they are used at the proper speeds and feeds. A reasonable investment in a spindle speeder might double or triple a microtool’s wear life and significantly reduce perishable tooling costs.

Plus, shop owners no longer have to turn down micromachining work because they lack the necessary capital equipment. The mainstay of the spindle speeder is their ability to let lower-rpm machine tools produce microparts, according to Vacio.

To read the entire case study, click here.

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.