I have several in line bores to machine for press fit bushings. They are pretty long bore to keep them in line. was wondering if this would be a option. Machines are horizontal g&l 5 inch spindles, cat 50 holders.

Ventajas de los sistemas de herramientas modulares

Cuantos más trabajos realiza su taller, más herramientas necesita tener en stock. Invertir en muchas herramientas diferentes y comprar más para cada proyecto es un gasto inevitable, un hecho de la vida en cualquier taller. Pero no tiene por qué ser así. Los sistemas de herramientas modulares rompen esa sabiduría convencional. Aun así son una inversión, por supuesto, pero una que ofrece características y beneficios únicos—y hace que asumir nuevos proyectos sea mucho, mucho más fácil. Vamos a hablar de qué son los sistemas modulares, algunas de sus aplicaciones y por qué la oferta de BIG DAISHOWA—el sistema de herramientas de precisión modular KAISER CK—es la mejor.

¿Qué son los sistemas de herramientas modulares?

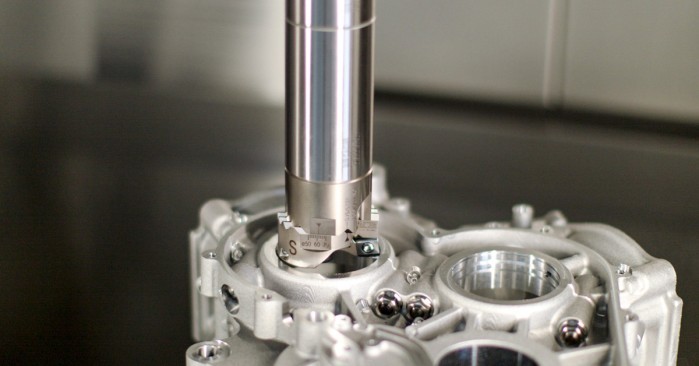

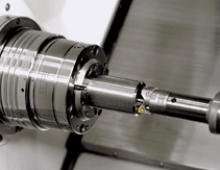

Un sistema de herramientas modulares es un conjunto de herramientas y accesorios intercambiables diseñados para operaciones de precisión. Permite optimizar y adaptar las herramientas para aplicaciones específicas, ajustando diferentes profundidades, diámetros, acabados o niveles de precisión según sea necesario. Los componentes se pueden ensamblar, ajustar e intercambiar sobre la marcha para cumplir los requisitos de una variedad de proyectos. Son increíblemente convenientes—y nuestro sistema modular incluye todas las partes relevantes:

- Vástagos

- Reducciones y extensiones

- Barras sólidas

- Barras de amortiguación

- Adaptadores de pinza

- Inductores de refrigerante

Conozca más sobre nuestros componentes específicos y sus usos en nuestras páginas de preguntas frecuentes aquí y aquí.

¿Cuáles son los beneficios de agregar un sistema de herramientas modulares a sus operaciones?

Las ventajas de las herramientas modulares afectan prácticamente todos los aspectos del proceso de mecanizado, ampliando sus posibles aplicaciones, reduciendo el tiempo de preparación y acelerando el retorno de inversión (ROI).

Aumentar la productividad y eficiencia

Las piezas modulares se pueden intercambiar rápida y fácilmente. En lugar de cambiar juegos completos de herramientas para cada trabajo, los operadores pueden simplemente reemplazar las piezas individuales necesarias. Esta intercambiabilidad reduce el tiempo de preparación e ingeniería, ofreciendo un ROI más rápido. Además, cuanto más componentes pueda intercambiar, más aplicaciones serán adecuadas para la herramienta.

Reducir costos de herramientas

Ya sea cortando o mandrinando, cada herramienta ocupa espacio y cuesta dinero. Con un sistema de herramientas modulares, puede ahorrar en ambos aspectos. Dado que un sistema modular puede cubrir las necesidades de muchos proyectos diferentes, no necesitará tantas herramientas de uso único para realizar cualquier tarea. En pocas palabras: puede hacer más con menos. Y como obtiene un ROI más rápido, recuperará su inversión en herramientas más pronto.

Mejorar la seguridad

Como los sistemas modulares permiten personalizar cada trabajo, las herramientas suelen ser más estables que sus equivalentes de uso único. La vibración y el “chatter” no son solo inconvenientes, sino riesgos de seguridad (movimientos inesperados de la herramienta pueden generar resultados no deseados). De igual manera, cada vez que un operario debe detenerse y cambiar una herramienta, corre el riesgo de accidentes o lesiones; al reemplazar solo componentes individuales, puede alejarse de la herramienta y volver al trabajo más rápido. Esto es aún más cierto para nuestros componentes modulares, que están diseñados para maximizar la rigidez, reducir la vibración y permitir un cambio rápido.

Reducir desperdicio

Con un sistema modular, se reduce el desperdicio en dos áreas clave: herramientas y materiales. Puede reparar o reemplazar componentes modulares individuales a medida que se desgastan, en lugar de reparar (o peor aún, desechar) herramientas completas. Y dado que las herramientas pueden personalizarse completamente para cada aplicación, se reducen los retrabajos y errores, generando menos material desperdiciado en cada proyecto.

Aumentar la flexibilidad

Cuanto más modular sea su sistema, más aplicaciones podrá tener, especialmente si es de alta calidad como los de BIG DAISHOWA. Cuando puede combinar componentes sin perder rigidez, puede usar sus herramientas para más trabajos sin pérdida de calidad. Imagine que alguien se acerca a su taller para un lote de producción de última hora con un plazo ajustado. Es una gran oportunidad, pero difícil de asumir sin un sistema modular.

Mejorar la calidad

Los sistemas modulares se someten a las mismas tensiones que los sistemas de herramienta única y deben mantener el mismo nivel de rigidez—a pesar de estar formados por múltiples componentes. Por lo tanto, cada pieza de un sistema modular debe ser tan fuerte (si no más) que una herramienta única. La calidad se maximiza para cada parte, asegurando que, sin importar la aplicación, el sistema sea lo suficientemente robusto para manejarla.

Mejorar la precisión

Cuando una herramienta se personaliza para un propósito específico, puede realizar esa tarea con más precisión que cualquier herramienta estándar. Ambas herramientas completarán la tarea, pero solo una ha sido diseñada específicamente para esa tarea exacta.

Simplificar la gestión de inventario

Los componentes de uso único son la pesadilla de cualquier organizador. Estar en un taller lleno de ellos puede sentirse como dentro de un cajón de cocina sobrecargado. Con un sistema de herramientas modulares, reducirá significativamente la cantidad de equipos de uso único—y el espacio que ocupan—lo que significa menos tiempo limpiando y organizando inventario y más tiempo obteniendo ROI.

Simplificar la configuración y operación

Configurarse para diferentes trabajos es tan simple y rápido como intercambiar las piezas necesarias. Dado que la herramienta siempre se adapta al trabajo, la operación también es más fácil.

Mantenimiento predictivo

La digitalización es cada vez más común en el mecanizado y ofrece muchos beneficios. Una característica especialmente interesante es el mantenimiento predictivo. Gracias a la monitorización del rendimiento en tiempo real, puede detectar fallas mientras la herramienta está en funcionamiento—y gracias a la modularidad del sistema, puede identificar los componentes individuales que pronto necesitarán ser reemplazados. Sin sorpresas y sin desechar herramientas completas.

¿Cuáles son algunas aplicaciones populares de los sistemas de herramientas modulares?

El sistema BIG KAISER CK tiene muchos usos y, debido a que sus componentes son altamente personalizables, son ventajosos en prácticamente cualquier situación. Todas las industrias pueden beneficiarse, pero son especialmente útiles para industrias que trabajan con una variedad de materiales y tienen márgenes de error reducidos.

Considere una empresa que fabrica moldes y troqueles. Podrían vender moldes y troqueles para la producción de todo, desde plásticos hasta productos de consumo o piezas automotrices. O piense en un fabricante de piezas aeroespaciales especializado en trenes de aterrizaje, palas de turbina y componentes de motores. Finalmente, imagine un fabricante de dispositivos médicos que produce implantes ortopédicos de titanio un día y componentes de microscirugía de acero inoxidable al siguiente.

En todos estos casos, las tolerancias son estrictas, las geometrías varían ampliamente y cualquier trabajo dado puede involucrar múltiples materiales. Con herramientas de uso único, cada una de estas empresas necesitaría mantener mucho equipo diferente a mano—pero gracias a las herramientas modulares, no es necesario.

¿Qué hace únicos a los componentes modulares de BIG DAISHOWA?

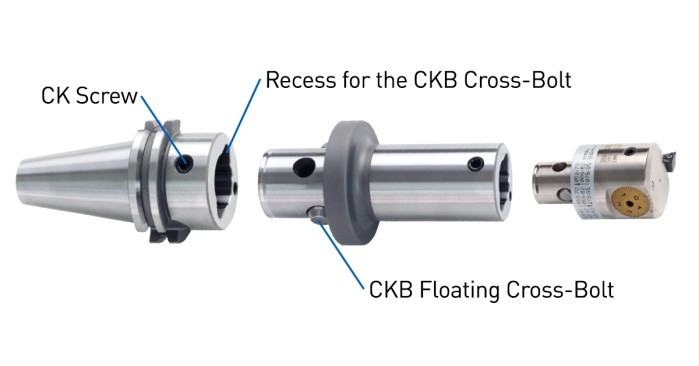

Todo sistema de herramientas modulares es versátil. Pero el sistema BIG KAISER CK—basado en conexiones cilíndricas con tornillos de bloqueo radiales—es el sistema modular más versátil del mundo. ¿Por qué? Es simple: cada conexión BIG KAISER debe ser compatible con todas las demás de nuestro catálogo.

Eso significa que casi el 100% de nuestras piezas funcionan entre sí. Además, a medida que nuestro catálogo de piezas se expande, también lo hacen las posibles aplicaciones de su sistema modular. Los componentes antiguos siempre serán útiles para sus propósitos originales—y con nuestros componentes, puede estar seguro de que también funcionarán con equipos más nuevos. Su juego de herramientas está preparado para el futuro. Y si necesita nuevos componentes, siempre están disponibles en stock.

Por supuesto, esa no es la única ventaja.

Simplicidad y resistencia

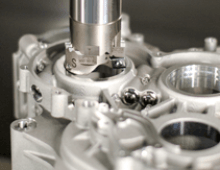

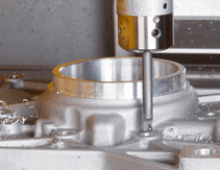

El sistema CK funciona con todas las interfaces de máquinas herramienta. Su sencillo tornillo lateral de bloqueo facilita enormemente la instalación de componentes, sin necesidad de equipos o herramientas especiales. Además, es extremadamente seguro. Las altas fuerzas de precarga y las grandes áreas de contacto garantizan la máxima rigidez sin importar el trabajo.

Precisión y facilidad de uso

Gracias a su estabilidad, las ubicaciones de corte del sistema CK se mantienen precisas incluso cuando se usan varios adaptadores. La precisión de intercambio es alta, con un error máximo de cambio radial de 0.0001” por conexión.

Ya sea necesitando menos herramientas, disfrutando de una configuración más sencilla o obteniendo un ROI más rápido, hay muchas formas en que su operación puede beneficiarse de un sistema modular. Contacte a su representante de BIG DAISHOWA para discutir cómo un sistema modular puede ayudarle hoy.

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.

Comments

John Zaya

Mié, 23/10/2024 - 08:28Hello Kevin,

I will send you an email shortly to discuss your application in more detail.

John

Kevin Oleck

Mar, 22/10/2024 - 15:44