North Carolina Start-Up Focused on Hybrid Machining

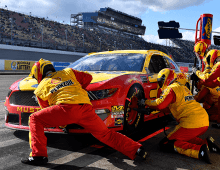

As factory openings go, it was altogether a splashy event with TV cameras and national media covering the launch of Keselowski Advanced Manufacturing (KAM) in Statesville, NC. All the attention was not too surprising given Brad Keselowski’s name recognition as a championship winning NASCAR driver who currently competes for Team Penske.

The event was equally deserving of attention by the manufacturing world for the bold vision laid out by Keselowski and his

management team. KAM promises to deliver end-to-end capabilities in engineering, hybrid manufacturing and quality control as a contract manufacturer for a range of industries from automotive to aerospace, defense and energy. “As the factory of the future, KAM will be a model in practice,” Keselowski said.

It’s a business concept that sounds great for sure, and the vision comes to life for visitors to the 70,000-square-foot facility in

North Carolina. It’s as welcoming, brightly lit and spotlessly clean as you can imagine any best-tech-company-to-work-for might be. “Impeccably maintaining our facility represents quality in manufacturing, but an orderly environment also shows respect to our people and a sense of pride in our work,” Keselowski explained.

The visitor area includes a dozen show cars as homage to the owner’s first career and his passion for speed. The rest of the facility is dedicated to engineering, material analysis, production and inspection. The aptly named subtractive room houses a neat row of new 5-axis and multi-tasking machining centers and wire EDM. Adjacent rooms are dedicated to tool management and quality control. The additive space houses the first two laser machines for printing metal, with future capacity for more than 75 similar machines.

The company’s value proposition is based on a “quality first” mindset in every part of the business, including vertical integration of manufacturing processes, and a fearless adoption and integration of cutting-edge technologies. In a speech to about 200 guests at the launch event, Keselowski explains his commitment to quality at each level, from the facility, equipment and tools to hiring staff, selecting suppliers and delivering product.

It’s a philosophy shared by the general manager of KAM, Steve Fetch, who was previously responsible for global quality at a leading 3D printing company. Now Fetch oversees KAM’s additive and subtractive machining processes, post-processing, and 2D/3D CT X-ray scanning to deliver complex, zero-defect parts with short lead times.

According to Fetch, it is both the capacity for serial production of hybrid parts and the full vertical integration of all of these processes that will make KAM unique as a manufacturer. “Our plan is to grow into Tier one, high-tech, high-volume production. We can do this with fast cycles of learning and customer feedback,” he said.

It seems logical that Keselowski’s passion for technology and manufacturing springs from an interest in how to build a winning

race car. But it’s clear the connection goes deeper than that, as he explains how he plans to apply many lessons from the business of racing at his new company.

“From engineering to production, I’ve seen the top teams tackle the biggest challenges with speed and reliability,” he said. “We

are ready to connect engineering and manufacturing to make parts never seen before. It’s the next industrial revolution.”

“It’s fantastic to work with a true entrepreneur like Brad Keselowski, and we are excited to be a partner with KAM for tooling and tool measurement systems. Brad has a bold vision for his company and great people on his team,” said Chris Kaiser, president/CEO of BIG KAISER. “We wish them all the best in this new endeavor.”

¿Te pareció interesante o útil? Haznos saber tu opinión agregando tus comentarios o preguntas a continuación.