5 Tips for Getting a Micromachining Job Right the First Time

The growing need for production of miniature parts and features in medical and dental applications – as well as moldmaking, fiber optics, automotive and other industries – has taken us beyond more sluggish EDM and laser processes. Such tiny tooling and part features are, by nature, challenging to manage. And at production-level volumes, achieving consistent quality is even more difficult. If you’re looking for ways to improve productivity with micro cutting tools, here’s what you need to know.

1. Know the angle of the entry point

An example of micro-drilling, this medical part contains 400 micro-holes.

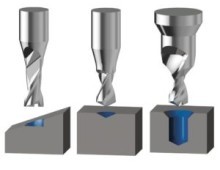

If the entry point on the part you are drilling is less than 10 degrees, careful feeding can get the job done. But if the angle is steeper, you’ll likely need to give the tool some help to prevent the drill from walking across the surface. You can do this by milling a small notch at the entry point, effectively creating a perpendicular starting point for the center drill followed by the drill.

2. Heat behaves differently with micro tools

Since the chips micro tools generate are naturally smaller, less heat is transferred to them resulting in less displacement from the tool and cut. In addition to an oil/air mist to help accelerate cooling and chip removal, consider using a machine with fine servo control to peck the hole and fully retract the drill, especially in high length-to-diameter ratio cuts.

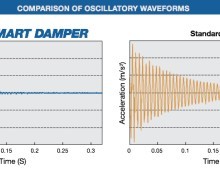

3. Use the right machine

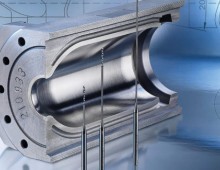

Runout and vibration are bad words when it comes to micro machining operations. So much so, that there are machines out there that minimize the R and V words, built specifically to perform these small cuts. Regardless of how much micro work you do, the right machine, capable of fine feeds and runout well below 0.0001-inch TIR is highly recommended. It wouldn’t hurt, but that doesn’t mean you need a 30,000-rpm machine. As long as runout and vibration in check, very small holes can be done at around 10,000 rpm.

BIG Daishowa high precision collets, made to class AA standards, provide stable runout and afford easy tool changes. Cleaning the collet during tool changes helps maintain repeatability.

4. Have the right skills on staff

With experienced micro-machinists, it’s almost spooky how they can sense when a micro tool isn’t performing. While there’s no substitute for experience, the skills are learnable. You have to commit to training your operators on the craft. Oftentimes what you know about cutting with more standard sized tools gets turned upside down when talk of microns and 80xD come in to play.

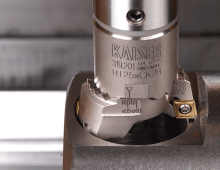

5. Count on your tooling vendor

We touched on the staggering variety available in the Sphinx line of micro tools. There’s good reason for it. There simply isn’t the structural integrity or margin for error to “bull” through a workpiece. So matching factors like material, web thickness and flute count to the specific part is critical to success. The most minor misalignment in any of these areas can have dramatic effects on the result. We recommend leaning on the tooling manufacturer when deciding the tool to buy. We’ve done all the testing. We’ve seen what’s worked and what hasn’t with other customers. And we know what kind of work was in mind with each product design. Plus, in those really those really tricky situations we can provide a custom drill for the job.

Here you’ll find our full offering of drills, our handy drill selection guide and tips for handling miniature marvels of engineering.

To learn more about these and other solutions for the medical industry, contact us or check out our latest High Performance Tooling Solutions catalog.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.