Japan Tech Tour Educates NTMA Members on Precision in a “BIG” Way

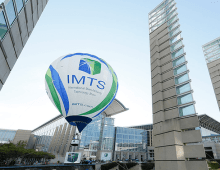

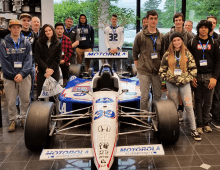

NTMA members visited BIG Daishowa Seiki in Japan during the association’s 2016 Tech Tour last month. The annual Tech Tour is a special opportunity for NTMA members to learn, network and tour manufacturing facilities outside the U.S.

During one week in Japan, 18 members were hosted by BIG KAISER, Blaser Swisslube, Mazak and MEMEX. Each sponsor demonstrated their latest manufacturing technology and lead tours at MAZAK, Chuo Iron Works, Sumitomo and BIG Daishowa.

“I really enjoyed the opportunity to tour some top-notch companies, learn about their products and business strategy, and network with other companies while at the same time getting to experience the Japanese culture and cuisine. Extremely valuable,” says Andrea Wosel, Project Manager at C&R Manufacturing near Kansas City.

NTMA Chairman Herb Homeyer, NTMA President Dave Tilstone, and BIG Daishowa President & CEO Joji Nakatani

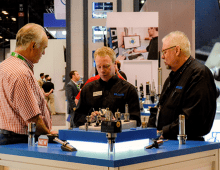

The day at BIG Daishowa on Awaji Island included tours of three of five factories, followed by machining demonstrations in the Mega Technical Center. Visitors were impressed with immaculately clean facilities and highly automated systems, many with custom-designed material handling.

At this location, the company produces standard products, like high-precision tool holders, in large volumes. The focus is on achieving the highest level of accuracy to guarantee highest machining performance. With meticulous in-process inspection of parts and 100 percent check of finished products, BIG Daishowa tool holders deliver better than 3 microns concentricity at 5 times diameter.

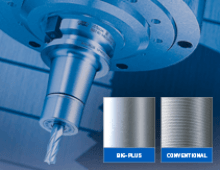

VP Engineering Jack Burley, from BIG KAISER U.S., also explained the benefits of the BIG-PLUS® simultaneous dual-contact system, an original product of BIG Daishowa. The Awaji facility holds the master gauges which set the standard for spindle builders worldwide, and ensure the ultra-precise tolerances of the BIG-PLUS® system.

“Their commitment to quality was evident in every aspect of their manufacturing process. From cosmetic appearance of the tooling to the inspection processes used to verify accuracy of their products, they are obsessed with making the highest quality of tooling above and beyond industry standards,” said NTMA President David Tilstone.

Along the way, there was time for Japanese-style meals and sightseeing in the historic city of Kyoto.

“I have heard nothing but rave reviews from the attendees on their experience,” said Tiffany Bryson, National Account Manager for NTMA.

View other photos here.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.