Answering Tricky Boring Tool Questions

There’s more than one way to make holes, but some approaches are better than others. On one hand, it’s nice to have options, but they also make decisions about tooling and processes a bit more difficult. Working with customers from across just about every industry, our team gets to see what works, what doesn’t and how others can learn. These are a few of the interesting questions—and unexpected answers—we talk about with end users.

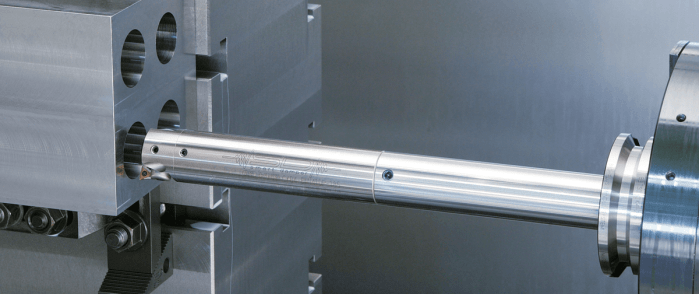

How many modular components can be used in a boring setup?

As always, the shortest possible setup is best. Modular boring assemblies using systems, like our CK precision tool system, unlock all kinds of possibilities for making this happen, including reductions, extensions and damping options. There are limitations, however. In any boring assembly, components should be limited to four or five, not including boring head insert holders. Considering the number of possible combinations, almost any hole can be accounted for.

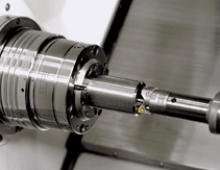

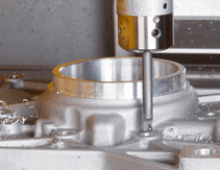

How do I stop burning through roughing cutters?

One way to help reduce consumable costs in rough boring is to limit the radial load. The best way to do that is to use more of a plunging motion as opposed to interpolation, which will eat away at the flutes from the sides. A twin cutter boring head is a great solution. It balances the load better, requires fewer inserts to begin with and ultimately makes perfect roundness easier.

When should l be thinking in terms of roughing and when should I be thinking in terms of finishing?

The most common differentiator is final tolerance. If diameter tolerance is tighter than 0.004", a finishing heads should be in the discussion. Learn more about this and four other factors to consider when deciding between finishing and roughing heads in this video.

How do I make sure I choose/assemble boring tools that are the right length?

There is more to the right-sized tooling than diameter and gage length. The bore depth and the reach to get to the bore need to be factored. In other words, if the bore is three inches deep, but the tool must reach five inches to get to the bore, you should be planning your setup for eight inches of reach.

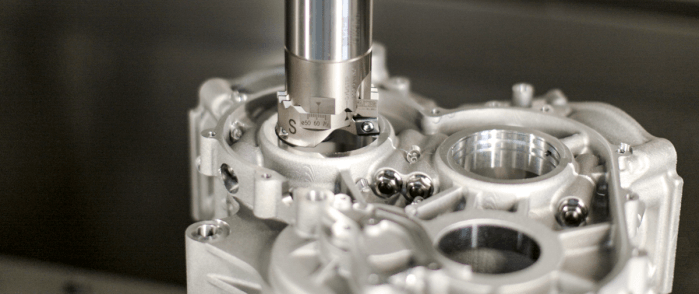

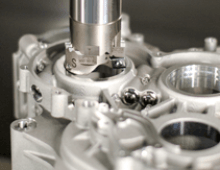

What is the best way to prep a hole before boring?

Rough and fine boring is best done after the workpiece has been milled to square the hole to the entry surface, including castings and weldments when possible. Fine boring tools should also enter a hole that has been chamfered, where the rough or semi bore is free of existing chatter or deep scallops created by rough milling.

Is there a better way to finish holes with hardened steel bushings?

Jig grinding is the common approach, and yes, it’s time consuming and requires a skilled operator. Boring tools with cubic boron nitride (CBN) grades have proven effective alternative, even in very small holes. Let your tooling do the hard work, not your operators.

Can I use an extended range insert holder for production and prototyping?

Shops often borrow in-house components from other applications and replace the insert holders. This can be a smart move in small-batch scenarios. Trying to get production out of the same setup, however, would yield adequate results, but not the most productive. An assembly using a larger modular connection size and boring head is better. That will reduce the L:D ratio and provide better balance with the insert holder closer to the boring head.

How do I get control of chips when I’m boring?

First and foremost, optimize the cutting speed. High cutting speeds usually lead to cutting conditions that maintain a consistent chip load. Identify a chip load in inches-per-revolutions (IPR) that generates the shortest possible, C-shaped chips. Even think about making a trial cut to optimize chip form. It can be worth it in the long run.

Seeing the diameter readout on a digital boring head is nice, but I’m not sure how I’ll get return on the investment?

Digital boring heads do much more, especially ours. When connected to the BIG KAISER app via Bluetooth, the incremental value from the EWE fine boring head can be fed into the preset parameters to give the true output diameter of the tool.

The head also stores up to 200 cycles of information (target diameter, tolerance, incremental adjustment) for each adjustment along with a date/time stamp, providing process traceability for certifications and planning.

We offer an array of hole making solutions for common and uncommon processes, including roughing, finishing, chamfering, back boring, drilling and more.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

Add new comment