New Opportunities Spurred by Economic Slowdown

2018 was a great year for manufacturing technology orders in the United States, according to the Association for Manufacturing Technology (AMT). The AMT records new orders for metal cutting, metal forming and fabricating equipment as a leading indicator of industrial activity and releases its findings. However, they report orders for machine tools this year have decreased compared to last year, thus indicating a downward trend within the industry.

But the news isn’t all bad for manufacturers. Despite the larger trend, different manufacturing sectors recorded growth in 2019, including the aerospace and automobile industries. AMT’s chief knowledge officer, Pat McGibbon, reassures that orders this year will still be good, but simply smaller than last year. “The U.S. manufacturing landscape continues to grow, albeit at a slower pace. This development, in conjunction with concerns about trade policy impacts on exports, points to a decline in manufacturing technology orders in 2019 over 2018.”

This general shift to slowing purchases nevertheless offers manufacturers a chance to re-think strategy and regroup. “It's great when we have the chance to tool up new machines for our customers, but when new machine purchases slow down, our focus shifts to optimization,” said Chris Kaiser, CEO of BIG KAISER. “That's where our product managers and reps can really make a difference. They've pretty much seen it all – different materials, applications, and machines. They know all of the tricks and tools and accessories that can be applied to save time, improve part quality and extend tool life.”

We offer several products that can help with such optimization goals. Presetters allow for higher speeds and increased precision to machining shops. Peterson Machining is a recent shop to integrate this tool—lead machinist Steve Carper says, “We always post from the presetter, so a tool is ready to go in any machine that can accept the tool. It could run 10 different jobs and we won’t touch it off again.”

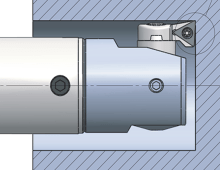

The BIG-PLUS spindle is another tool geared toward optimization. It substantially improves the rigidity of a tool, thanks to simultaneous taper and face contact between the tool holder and machine spindle. The result is improved surface finish and accuracy and extend tool life.

Accessories should not be overlooked by shops when looking to reach their goals. The gage bar is used to regularly inspect spindle accuracy, which then extends spindle accuracy, translating into lasting superior part quality. No matter your specific optimization goals, BIG KAISER offers a variety of tools and products to help you reach them.

To learn more about any of these products or see how BIG KAISER can help optimize your application, contact us.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.