Time to Reconsider Holding Taps with Collet Chucks

The next time you think about setting up a tapping operation with a collet chuck the same old way you always have, you may want to think again. There are now tap holders designed specifically to mitigate the load imposed on the tap by essentially absorbing synchronization error.

Tapping holes strikes fear in the hearts of machinists everywhere. Ok, that may be a bit of an exaggeration, but it is undoubtedly one of the more challenging metalworking processes to execute with precision in volume. Generations of machinists that came before, however, likely wouldn’t be too sympathetic. As recently as the 1980s, tension-compression tapping was widespread. This involved underfeeding tapping holders with springs, allowing the tap to travel independently on the way in and out – a painstaking process that could only be performed at rpm levels in the hundreds. In the years since, machine builders have done their part to help spare machinists the pain sometimes associated with the process.

Thankfully, most machine tools now come with canned cycles allowing for M-code and G-code pairings that precisely synchronize the spindle and feed axis for repeatable harmony with the workpiece . . . rigid and synchronous tapping. Built-in encoders can even monitor these activities and adjust the machine to maintain the proper relationship between feed and speed. Thanks to these advances, machines can now perform tapping with spindle speeds exceeding 4,000 rpm. Still, in the wake of these dramatic advances, limited tap life, poor thread pitch or tolerance and, most impactful, broken taps can keep machinists up at night and cost shops efficiency. Regardless of programming enhancements, it’s still a challenge to synchronize depth (especially in blind hole scenarios) and thread pitch with the relatively violent stop/reverse.

This brings the quest for more reliable tapping to a key variable outside of the machine itself: tooling. When it comes specifically to holding taps, the majority of shops opt for collet chucks. They’re easy to understand and set up, and they are generally well balanced, with strong runout characteristics. What many shops don’t realize is that another perceived strength of collet chucks, their rigidity, can actually be detrimental in tapping. Rigidity does very little to counteract the dramatic thrust loads imposed on the tap and part, exacerbating the already difficult challenge of weathering the stop/reverse and maintaining synchronization.

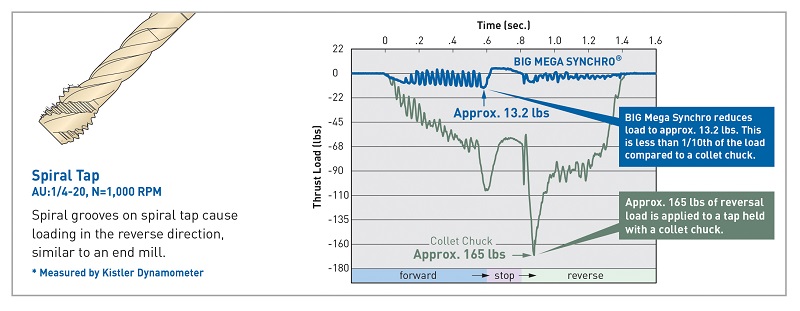

Using a dynamometer, we measured the load on a spiral tap held with a collet chuck in aluminum with metrics of 20 m/minute, 1,050 rpm and a depth of 12 mm. At the start of the reversal, the load was approximately 165 lb. It’s the resulting axial pressure that leads directly to breakage, poor tap life and inaccurate threads. If you’ve had to EDM a tap out of a hole, or even scrap a part, you understand the disruption breakage cause. While continuing difficulties with tap life or poor thread quality add up quickly in terms of real cost, you’re still not going to guarantee results or maximize the floor’s capacity if slowing down spindle speed is your solution. Just like machine builders have done their part, I’m here to tell you that we tooling suppliers are doing ours too. There are now tap holders designed specifically to mitigate the load imposed on the tap by essentially absorbing synchronization error.

For example, the Mega Synchro tapping holder is held into the main taper adapter with a cross bolt. The bolt goes through the outside of the cave and through the adapter, locking it in place. The hole in the adapter that houses the bolt has what we call a synchro adapter, an elastomer bushing that cushions the bolt. It’s this relationship between the cushioning and the bolt that allows for the right amount of float. This cushioning is enacted not only at the bottom of the hole during reversal, where rigidity and peak forces lead to breakage, but throughout the entire cutting process. This means more consistent control of thread pitch and tolerance while eliminating re-cutting on exit, even on machines capable of high speed retractions. The reduction of force also results in significantly less tap chipping that extends tool life, regardless of spiral angle – by a factor of more than two in most cases.

Just how much force can a little cushioning in the tapping holder reduce? Using the dynamometer to measure force under the same parameters as detailed previously in our test, but replacing the collet chuck with the Mega Synchro, the load maxed out at about 13 lb, or more than ten times less. Today’s shops are fortunate to have machines with specialized coding for this difficult process. Coding is not a cure-all, however. Using the proper holding equipment for tapping operations is the only way to maximize machine tool capabilities and compensate for synchronization errors that are still unavoidable. The next time you think about setting up a tapping operation with a collet chuck the same old way you always have, you may want to think again.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.