Digitally Connected Tooling Systems

To focus on getting the right product to market at the right price at the right time, manufacturers must realize the importance of data collection and analytics and how digitalization can improve competitiveness.

With the growing availability of the Industrial Internet of Things (IIoT), technologies can be made smaller with cheaper, more powerful sensors embedded inside. Internal sensors allow users to keep track of processes, manage them, and monitor statuses to improve productivity.

“Shops should consider upgrading to digitally connected tools because they can improve their production rates,” explains Nick Jew, research and development engineer, BIG KAISER Precision Tooling. “They can improve maintenance and track all of their information.”

Implementing digital technologies

To begin using digital technologies, start small. Nick Jew, research and development engineer at BIG KAISER Precision Tooling, suggests starting with one machine first, which usually requires only one day of training. Add a couple of digitally connected tools or expand the machine control to have network capabilities. As shop floor workers get more accustomed to the technology and begin seeing benefits, operators can start ramping up and implement it further.

“The potential for digitally connected tools is constantly growing.” Jew says. “In the future, as long as we can continue to downsize the sensors and electronics that go into the tools, you can essentially have every tool connected in ways that allow for constant monitoring of vibration, temperature, and all cutting information that used to be guessed at with analog tools.”

Now, manufacturers can start integrating digital sensors and provide real-time information to improve cycle times and prevent tool crashes or damaged tooling.

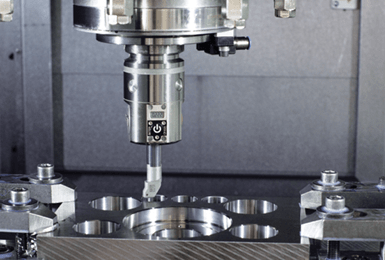

Bluetooth enabled boring tools

BIG KAISER boring tools historically incorporated analog designs, and the diameters had to be read through a dial marking on the edge of the tools that had to be rotated manually for adjustments. New, upgraded tools include an embedded digital screen with Bluetooth technology, allowing the operator to make adjustments more easily and accurately. If an error occurs, operators can look back and see exactly where the adjustment was made incorrectly.

With a Bluetooth-enabled head, operators can enter calculations or measurement values directly into BIG KAISER’s mobile app. It eases monitoring and configuration of the head while assembling and running boring tools. While tracking changes in cutting diameter, the app allows operators to determine optimal cutting parameters for their tool assemblies. It also logs historical adjustments for every tool synced with it, providing essential information for companies adopting smart manufacturing. And as users make adjustments, the screen displays how close the user is to reaching the preferred value. This reduces the chance for operator mistakes.

Programming a bore size with the app requires two steps.

- The operator enters the target bore size with tolerances. Tolerances can be entered manually or ISO tolerances can be selected from a drop-down menu.

- The measured diameter from the last part produced is entered, and the app uses the incremental adjustment signal sent from the boring head to show the actual output diameter produced by manual adjustment of the boring head.

“Other machines could potentially take this information directly and keep track of the adjustment values and confirm that the tool is adjusted correctly,” Jew explains. “It’s getting closer to a closed-loop automation cycle, making it possible for all machines and systems to communicate.”

He continues that BIG KAISER is currently working on this type of system, but for closed-loop automation of the boring to be easier to adopt and grow in the industry, there needs to be a standard for intramachine and intermachine communication so machine builders and tooling suppliers are using the same systems and processes.

Digitally connected tools for aerospace

In the aerospace industry, it’s especially important to have access to a tool’s saved history because it’s required to have that large amount of documentation throughout production. The enormous amount of data captured by the sensors used in these tools open deeper insights into operations and critical components. Having these devices connected allows a shop floor manager to constantly keep track of tooling and not just make guesses.

Instead of having to examine each tool, managers can get the information directly without waiting for the operator. It speeds production by eliminating some of the steps in the process.

Tools require a certain skill set to be able to understand the amount of adjustments needed to know how to read specific dials. With this technology, being able to see it on the screen, it’s easy and intuitive. Managers especially, can obtain more information from every device, which will help improve production and reduce maintenance costs.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.