I have customers all the time asking me to balance electroplated superabrasive grinding wheels spinning at 3-8K sfpm where unless its a multipart assembly 72cts psi vs .2-5g imbalance barely compensates for wheel wear after first pass....but the standard exists so I have to charge for the service...smart?

To Balance, or Not to Balance Tool Holders?

A lot of conflicting information has circulated about balancing tools over the years. As one of the authors of the new ISO standard for balancing, allow me to clear some things up, and hopefully make life a little easier for you.

An argument can be made for balancing almost every tool put in a machine. In the world of rotating tools, small changes to an assembly like a new cutting tool, collet, nut or retention knob can put an assembly out of tolerance. It stands to reason that any unbalance could possibly translate to the part, tooling and/or machine spindle in harmful ways.

You’ll hear the case for balancing tools based on long-standing ISO 1940-1 standard. Since its institution in 1940, the G2.5 balance specification has been a widely accepted standard across the industry— “it’s how things have always been done.”

However, faster machines were not considered when we documented our original ideas about balancing decades ago. Back then, the most advanced machines would have spun larger, heavier tools at a max speed of about 4,000 RPM. If you tried to apply the math from those days to today, you’d get impossible, unachievable values.

For example, the tolerances defined by G2.5 for tools with a mass of less than one pound rated for 40,000 RPM calculates to only 0.2 gm. mm. of permissible unbalance and eccentricity of only 0.6 micron. This is not within the repeatable range for any balance machine on the market. Similarly, application-specific assemblies, for operations like back boring and small, lightweight, high-speed toolholders simply cannot be accurately balanced for G2.5.

Machine tool builders rely on an outdated number too, often basing spindle warranty coverage on using balanced tools at very specific, close tolerances. While it’s true that poorly balanced tools run at high speeds will wear a spindle faster, decently balanced tools performing common operations will not wear spindles or tools drastically while still delivering the results you are looking to achieve.

Rule of thumb

This all begs the question, when do you really need to take the time to balance holders? I would argue that tools should only require balancing if they are notably asymmetrical or being used for high-speed, fine finishing. There’s a rule I’ve long followed: For any given tool, if the cutting forces exceed the centrifugal forces due to unbalance, high-precision balancing is not needed, because the force you need to balance the tool should be less than what the cutting forces are.

In other words, if you’re rough milling with a heavy radial cut, the different forces will start bending the tool. When that happens, the cutting forces and all the feed forces are going to be substantially higher than whatever the unbalance forces might be. If that's the case, it's not that you take the unbalance force and add it to the cutting force and find your adjustment. At that point, it's the aggressive cutting alone that’s going to do damage to the spindle, not unbalance.

I also see unbalanced tools being blamed for issues that turn out to be misunderstandings about a machine’s spindle. I’ve visited shops with brand-new, high-speed spindles that were still having issues running micro tools over 15,000 RPM. On the advice of their machine tool supplier, they took the time to rebalance all the tools in the machine with no improvement. It turned out the machine was tuned for higher torque and higher cutting forces. Before going to the effort of balancing tool holders, be sure you work with your machine builder to understand where a spindle is tuned.

Balancing tools can be risky

Not only is balancing tools rarely necessary, it can be risky too. Inherently asymmetrical, KAISER fine boring heads are a good example here. We balance them at the center a neutral position of the work range, but as you adjust out or in, you naturally lose that balance.

To adjust, one would typically add weight to the light side, which can be a problem for chip evacuation and an obstructor. Or, you can remove weight from the heavy side, but that means you have to put some big cuts on the same axis of the insert and insert holder, ultimately weakening the tool.

In longer tool assemblies, common corrections made for static unbalance can cause issues too. It happens when a toolholder is corrected for static unbalance in the wrong plane, i.e. adding or removing weight somewhere on the assembly that’s not 180 degrees across from the area where there’s a surplus or deficit. Once the tool is spun at full speed, those weights will pull in opposite directions and create a couple unbalance that often makes the situation even worse.

If you do go down the road of balancing, you must know where you can modify tools, what’s inside, how deep you can go and at what angles. I highly recommend, whether you’re adding or removing material on a holder, consulting the tool manufacturer for guidance first.

A cautionary tale

As a cautionary tale, consider a customer who was attempting to balance a batch of our coolant-fed holders. Based on the balancing machine, the operator drilled ¼-inch holes at the prescribed angle into the body of the holders. Not realizing what was inside, he drilled into cross holes connecting coolant flow and ruined several holders.

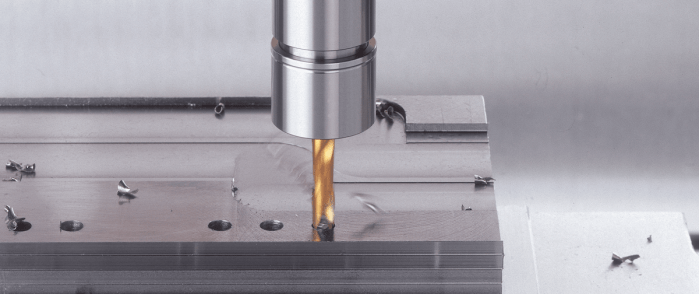

Tooling manufacturers are doing our part to help avoid disasters like this and other balance issues. For most tooling manufacturers, simple tools like collet chucks or hydraulic chucks are fairly easy to balance during manufacturing. At BIG DAISHOWA, we account for any asymmetrical features while machining and grinding holders and pilot each moving part, ensuring they will locate concentrically during assembly. These alone can make sure that the residual unbalance of the assemblies is very, very low and eliminate the need for balancing.

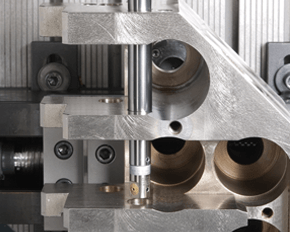

Auto-balancing boring heads are designed specifically for the high-speed finishing mentioned earlier, where unbalance force can actually be more than the cutting force. Our auto-balancing EWB boring heads, for instance, have a small internal counterweight that moves in direct proportion with each adjustment. Because the weight is carbide, it’s three times more dense than the steel in the tool carrier and is maintained inside the symmetrical body of the fine boring head.

Decades of the same standards have us conditioned to think a certain way about balancing tools. Admittedly, it does seem logical that every tool would need to be balanced. It’s just not the case: many of the issues attributed to unbalance aren’t actually unbalance, and the risk of balance often isn’t worth the reward.

Save your balancing time and resources for the high-speed, fine finishing work. If you do have work where balance is crucial, consider how the tools you buy are balanced and piloted out of the box and/or consult your partners before making any modifications.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

IAIN HALL

Tue, 11/04/2025 - 20:21