6 Tips for Tooling Up a New Machine Tool

The addition of a new machine can be exciting for a metalworking business. It signals progress, growth while giving the team something new and exciting to work and experiment with. In order to make the most of this investment, however, don’t overlook the tools you put into the new machine tool.

When someone buys a machine tool they’re thinking about things like speed, axis movement or the speed of the tool changer. It’s understandable. These upgrades can take seconds or minutes out of cycle times. But In order to take full advantage of its capabilities, you must have the tooling on hand to unlock a machine’s full capability and satisfy what customers are looking for. Here is some of our best advice for making the most of a new machine tool with the right tooling.

1. Communicate early with your machine tool salesman

We see it fairly regularly, a shop really wants the size and power of a 50-taper machine, but there isn’t quite the budget for it. So, the shop opts for a 40-taper machine and eventually finds out it doesn't have the needed horsepower or torque. There’s no going back now, so they try to compensate with tooling and variable-cut milling programs to limit the torque and horsepower requirements. This can not only slow things down, but also creates a mismatch of tooling for the machine and/or work.

Communication upfront with your valued machine salesman is key. Make sure they understand what your needs as far as capacity and what you’re looking to manufacture, all the way to the 1% of work that could come across the machine that may cause a problem.

2. Consider your spindle

Each spindle style comes with a unique set of standards, whether it’s a more conventional CAT or BIG-PLUS, or something a bit more specialized like HSK or Capto. If a facility is already heavy on one type of spindle or another, you’ll want to consider the costs of adding an entire new type of tooling as opposed to using the equipment and knowledge already on the floor. The higher speeds you plan to work at the more you’ll want to consider BIG-PLUS or HSK because of their proven track record.

3. Get to know your tooling supplier

When investing in a new machine tool, it’s important to take the time to look into the tooling suppliers as well. For example, there are a lot of tooling companies right now that are not manufacturing from H13 or tool steel. Those tools are not going to have the life expected to pay for themselves. There’s a good chance that a cheaper tool holder will run for about six months before runout problems pop up—even on a brand-new machine.

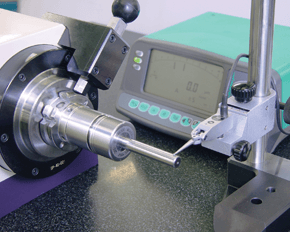

In addition to material consistency and quality, you’ll want to understand how a tool manufacturer qualifies its standards. For instance, where do they measure runout? If it’s measured in the taper, it doesn’t really tell you all that much. But if its measured at some multiple of the tool’s diameter in front of the nut, it’s a much better indicator of what a shop can expect from that tool.

If you take the time to understand how tools are made, what the tool manufacturer guarantees and why, you can make a one-time investment, likely for the life of that machine (assuming the tools are properly cared for). That’s a real cost savings.

4. Don’t overlook retention knobs

They may be relatively inexpensive, but retention knobs may be the last thing between you and a catastrophic collision or break. This is not an area to skimp. Don’t pull an old knob out of the coffee can in the corner. We can’t tell you how often we see piles of retention knobs that are either damaged or have been deformed due to being used in another machine over and over. This is especially risky in a new, precision-ground machine. Retention knobs should be treated as perishable and shouldn’t be repurposed for a new machine or tooling.

5. Understand the difference between licensed vs. unlicensed tools

For those buying a machine with a BIG-PLUS spindle, many don’t realize the damage they can do when they use a non-licensed holder a licensed spindle. It’s kind like Russian roulette. You might have seven of 10 tools that work pretty well, but it’s the three that are taken in and out that can ruin the face or taper of a machine. Then, none of the other tools are going to perform as they should. It’s just not worth the risk after investing so much in a new machine.

6. Understand your tooling certificate options

Ready-to-run packages appear to make things easy on the tooling front, but the truth is you’re likely only getting a handful of tools that even apply to the work you do. The rest will burn a hole in your shelves. Tooling certificates, available from distributors or machine tool companies, act like a debit card. Not only does it allow for building a custom shopping list that’s already paid for, but they provide direct and ongoing access to tooling engineers who can help find exactly what you need today and as work evolves. In the end, having a resource who knows your shop, machinery and work history can pay big dividends.

Investing in Tooling

Would you put discount tires on a Porsche? Probably not. So why invest hundreds of thousands in a machine and then dedicate a tiny percentage of that expenditure to tools? Your existing tool holders may look in good shape to the naked eye, but nearly any imperfection will find its way to the spindle of a machine that’s fresh off the truck.

During a shop visit recently, we saw a highly reputable machine known for its best-in-class accuracy, that had been installed just weeks before. They had 60 tools in a 300-capacity magazine and wanted to fill in some of the empty spots. The tools already in the machine were inexpensive and unlicensed. The customer thought these were the right choice because they were about a third of cost of licensed BIG-PLUS tools the OEM recommended.

One look revealed the tool holders were all fretted on the side. The spindle was damaged. They had to buy a new spindle for a million-dollar machine that was just weeks old.

In other words, do your homework, communicate openly and ask questions of those you’re working with during the machine purchase. If you do, you’ll get what you expect out of your capital investment, avoid unnecessary expenditures and realize significant cost savings over the life of the machine tool.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.