Spindle Maintenance Ensures Machining Performance

A machine’s spindle is one of the key links in the machining chain. In other words, if there are irregularities inside or at the face, they can show up on your part. It makes regular inspection and spindle maintenance critical to getting the most out of your equipment and maintain process efficiency. These accessories can help you perform this maintenance easily without eating into valuable spindle time.

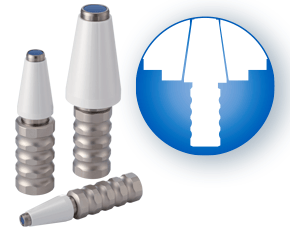

Spindle taper protection

The Dyna Contact taper gage makes verifying taper accuracy simple. All the operator must do is apply blue dye to the ceramic gage, insert it in the machine spindle and remove it. A quick visual check will reveal any improper contact points inside the taper.

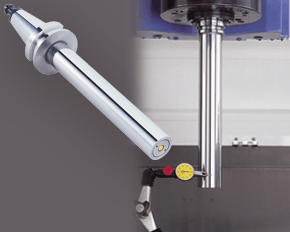

Static accuracy inspection

Another way to ensure your spindle bearings are good and ensure quality control is to measure its static accuracy. Using something like our Dyna Test bar, which inserts into the taper and extends out, is one way to do this. With the help of a dial indicator, you can uncover any runout while safely spinning the spindle at a very low RPM and verify the parallelism of Z-axis motion.

Retention force verification

Finally, in the machinery category, let’s talk retention force. The clamping mechanism in your spindle reduces chatter while ensuring rigidity and reliability. Like any other mechanism this can wear, making regular inspection a smart idea. The Dyna Force measurement tool provides a precise digital reading that reveals reduction in retention force in increments of 0.1kN.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.