Living the Challenges & Opportunities of IIoT

Usually recognized as a supplier to the metalworking industry, BIG KAISER is of course also a manufacturing company, facing similar challenges and opportunities as the customers we serve. For us, what we can generically call “Industry 4.0” deserves consideration both in our production facilities and in the design and manufacture of new products for our customers. We are mindful of the benefits and the trials of implementation on both sides. When concepts sound good but the reality is intimidating, it helps to focus on some incremental and actionable steps.

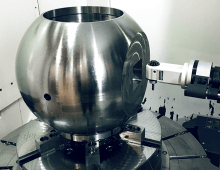

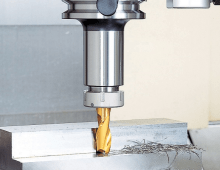

At the upcoming NTMA Fall Conference, we will participate in a session called “Job Shops of the Future” where we share our experience implementing a fully automated manufacturing cell at our facility in Switzerland. The new cell unites a machining center, turning center, tool pre-setter, robot and storage tower all under the control of production software. Keep in mind this is not a large manufacturing facility. The Swiss plant has a total of 15 or 20 machining centers and some grinding equipment, and generally produces small lots of 1 to 100. Our goal is to help NTMA members learn the pros and cons, and understand how and when to apply similar production strategies in their own businesses.

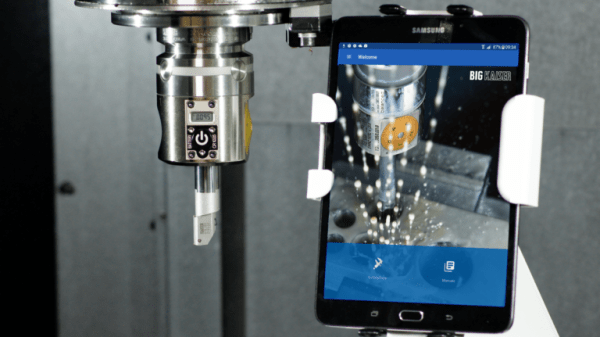

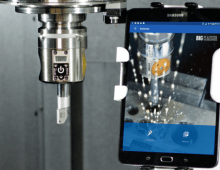

If you don’t plan to attend NTMA Fall Conference, we have more ways to help our customers along the path to Industry 4.0. In our regular column in Fabricating & Metalworking, authored this month by VP Engineering Jack Burley, learn about our free app for boring applications. It delivers data for easier in-machine adjustments, critical measurements and stores and tracks setups. Having this type of precise information available on-demand and in the palm of your hand enables smarter, faster decision making. Read the full story here.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

Add new comment