Tools, Holders and Runout: Uncover the Hidden Savings

To achieve peak performance, runout must be controlled.

For the sake of this column, we’ll call peak performance cutting at impressive speeds and feeds while maximizing tool life, i.e. more runs per tool and lower cost per cut. And just so we’re on the same page, runout in machining is when the center of rotation doesn’t coincide with geometric center of the spindle assembly causing radial motion. You may be asking, “Just how much can a little wobble really increase my costs?” Well, we set out to find an answer to this very question.

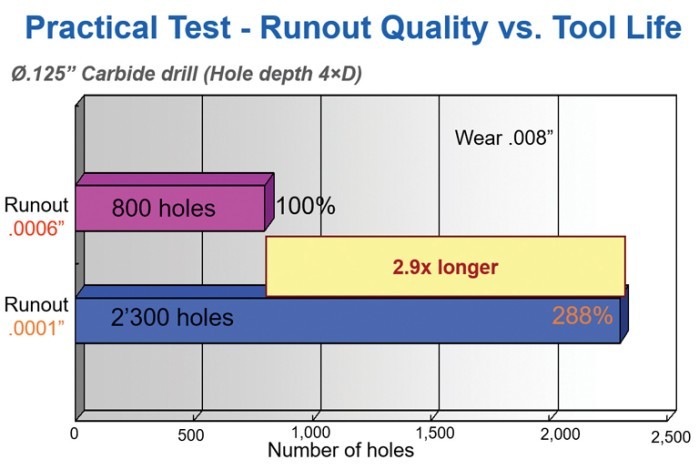

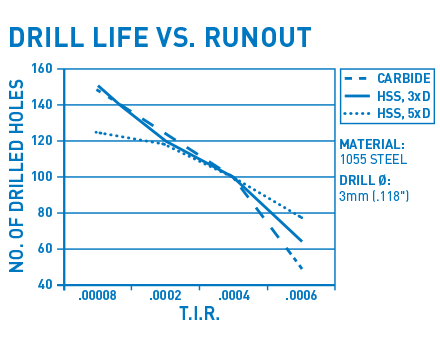

At the BIG Daishowa Mega Technical Center in Japan, we tested carbide drills at four different runout values, ranging from .00008 in to .0006 in on a 1065 steel part. Each drill ran until we measured wear of .008 in, at which point the drill’s tool life was considered expired. The Ø3 mm carbide drill was good for 148 holes at runout of .00008 in for a cost per hole of $0.27. We separately and informally asked some customers what they considered good runout. The consensus was .0005 in. At that level, the cost per hole tripled from $0.27 to $0.57. Now that we’ve established that there is value in an ever-so-slight wobble, let’s touch on how to manage runout when it comes to the tool portion of the assembly.

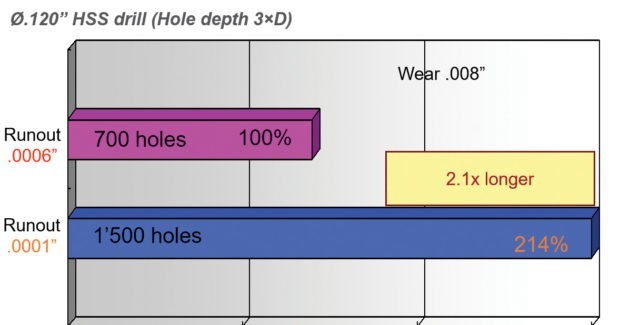

Of course, tool size plays a role; the length-to-diameter ratio and mass are going to affect force as it spins. But it’s also important to note that two different sized tools cutting with the same amount of runout can result in very different outcomes. The larger the tool, the more resistant it is to runout. We’ve also seen how different tool materials cope with runout. In most metalworking setups, carbide tools are the gold standard: durable and precise. In a separate test, we put nearly identical carbide and HSS drills against each other in the same runout scenarios. We ran a Ø.125 carbide drill at 4xD and a Ø.120 HSS drill at 3xD each at runouts of .0006 in and .0001 in.

Unsurprisingly, the carbide drilled more holes before failure. What was of note was that carbide, in terms of tool life, appears more sensitive to runout. The carbide drill lasted 2.9x longer at the lower runout level and produced 288 percent more holes. The HSS drill, on the other hand, lasted only 2.1x longer and made 214 percent more holes at the better accuracy. Coolant also proved to add to the tools’ edge resistance to wear.

While the tool itself plays a role in managing the cost of runout, its holder has even more of an impact. The more precision and strength a tool is held with, the less runout. This allows for more balanced tool wear, which translates to longer tool life at more productive speeds and feeds.

Much of holder effectiveness comes down to where metal meets metal: taper-to-taper contact, nut-to-collet face, the collet angle and pullstuds. Don’t overlook the tail end of the holder. The higher the ratio of taper contact, the less runout you’ll see. We recommend holders that are precision machined. Our Mega Chucks, for example, are designed and built with this in mind. Machined to sub-micron tolerances and micro-mirror surface finishes, they achieve at least 96 percent taper-into-taper contact. You’ll also want to mind the point of contact where the holder grips the tool. In a typical collet chuck system, for example, the standard angle of the collet is 16 deg. With 16 deg, a single collet can have a clamping range of Ø1 mm (.039 in), a feature that most users find very attractive due to the wide clamping range. However, the trade-off is less runout control and less clamping force to grip the cutting tool securely than say a chuck at 12 deg with a range of Ø.5 mm.

Upgrading to a collet nut with ball bearings over a tradition solid nut also offers better control of your operation. As a solid nut is tightened, torque forces will twist the collet when adding the last few degrees of a wrench pull. A bearing nut, although more expensive, provides smooth clamping with low torsion force on the collet. This allows for enhanced gripping force, better runout control and less collet wear for longer collet life. Often viewed as cheap and replaceable, pullstuds shouldn’t be overlooked especially when it comes to runout. A pullstud screwed into a tool holder that does not align to the same centerline as the taper and/or retention system will impart lateral forces against the system. These studs should be made of strong metals and precise to resist deformation and locate accurately. It’s why our studs are built with through-hardened H13 premium tool steel and all features are precision ground.

Runout can be fickle, but finding a solution for it can pay significant dividends. Remember the gap in savings between what users thought was good runout and a modest improvement? Keep this knowledge in mind, run a few tests and you’ll surely find hidden savings in productivity and consumables that add up quickly.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.