A More Productive Alternative to Helical Interpolation for High Volume Holemaking

The limitations of using milling tools to prepare holes for finishing become apparent as hole depth and volume increase. Enter the relatively simple and affordable twin cutter, which can solve this and virtually any other holemaking problem.

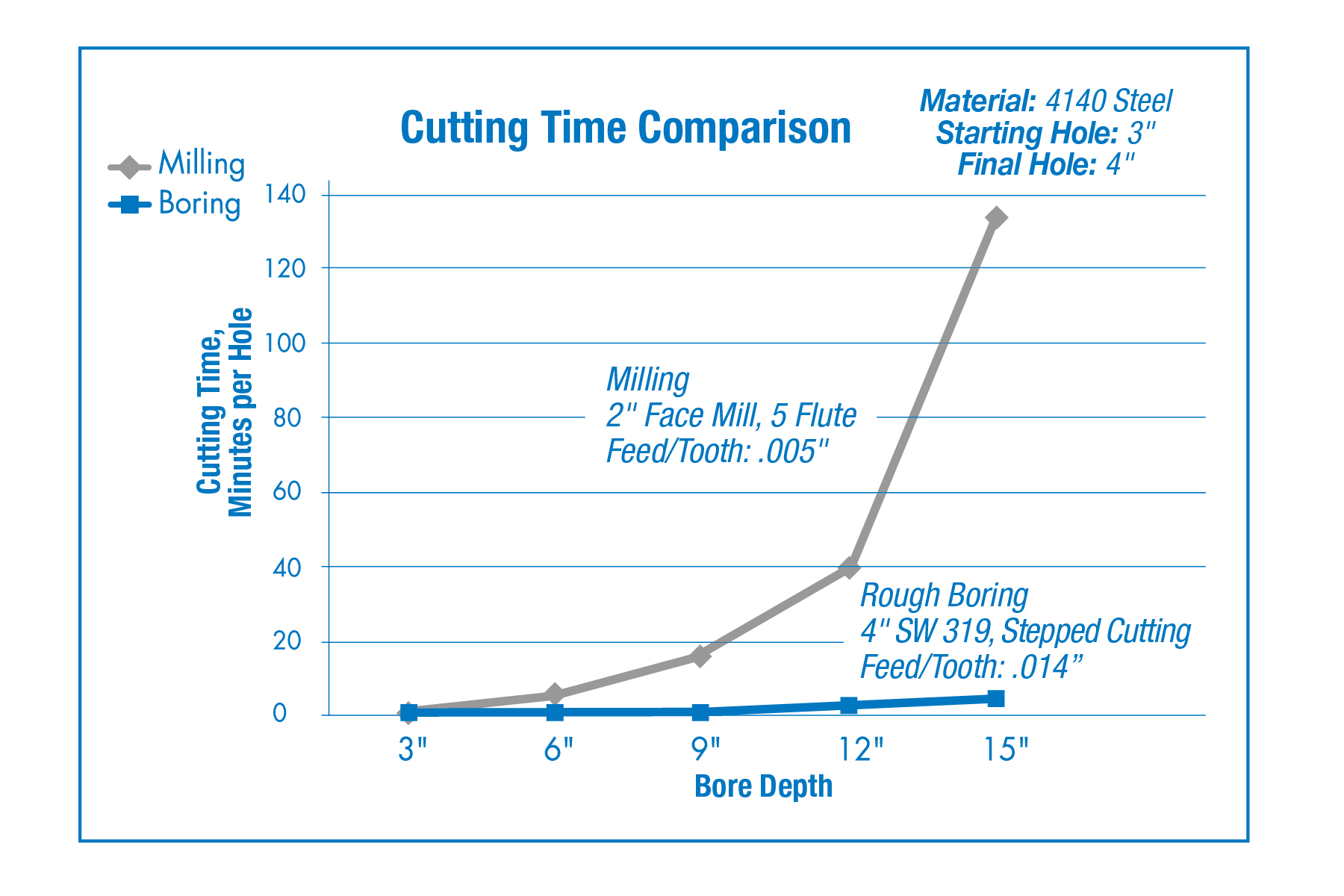

Helical interpolation using milling tools is a useful, tried and true method of preparing holes for finishing. Simultaneously rotating the cutter and moving it axially at a defined pitch makes a range of diameters and profiles – such as wide shoulders – possible with one tool by simply making more expanding sweeps. As hole depth and volume increase, however, limitations in this approach reveal themselves. A sufficiently rigid end mill can only be so long, requiring more and more time-consuming steps as depth increases – and the depth of the hole itself is limited.

As the end mill lengthens, deflection becomes harder and harder to avoid because of the dynamic radial load. An operator could always make extremely light cuts as the mill moves through the hole, but that is a drag on cycle time that’s not viable in production. Another variation is to use a helical milling cutter to perform heavy-duty cutting in the same circular pattern, but it’s only possible at very high horsepower – the kind of horsepower that’s not available to every shop. What’s more, in all of these scenarios there’s a constant single-side load on the tooling and spindle as the axes are changing and the tool is fed in – a potentially harmful force for even the most robust machine tool and its bearings.

That brings us to boring as an option. Most often, this involves a starter hole created by a drill and a series of boring bars set to increasing diameters for stock removal one pass at a time. This will yield a straight and accurate hole, but it’s a pricey and relatively expensive cycle with so much tooling and time involved. All of these aforementioned approaches may be suitable for one-offs or small batches, but it would be difficult for a shop to rely on any of them for consistency and efficiency in a production environment. Fortunately, another technique comes to us from the boring world that I firmly believe is best for holemaking production. It doesn’t require elaborate setups or creative cycles, but rather a relatively simple and affordable tool that can be used on most any machine, CNC or not.

The addition of a twin cutter boring head to a shop’s tooling arsenal opens the door to multiple homemaking options. Once thought of only as light-duty, semi-finishing tools, today’s high performance twin cutter boring heads have proven they can deliver in holemaking operations. Quite simply, once a starter hole is established with a drill, a twin cutter is plunged axially to remove the rest of the stock. This offers several natural advantages over helical interpolation and other similar processes:

- The plunging motion results in axial load as opposed to radial, preserving the machine and spindle components.

- Superior load balance in the cut makes for reliable and consistent performance, especially noticeable in long-reach applications.

- Milling tools can have multiple inserts per flute which is costly, while the aptly named twin cutter only requires two.

- A consistent inline feed requires less programming than the stepped removal required of an end mill or multiple boring bars.

- The two-edge effective tool enables faster feed rates and reduces cycle time.

- Perfect roundness is easier to achieve with more consistently in preparation for finish boring.

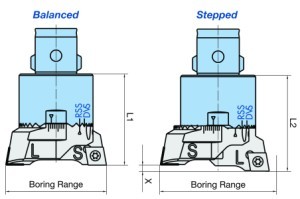

Twin cutters are most often used for rotationally symmetric rouging where the edges are balanced in both height and diameter. This is an ideal arrangement for light to medium cuts, because the strength and rigidity of the direct balance makes very high spindle speed and feed rates possible.

Sounds good, right? It gets better.

The real power of twin cutter is realized when it’s used outside of its balanced applications, most notably in stepped cutting. Also known as double offset roughing, this is when the insert holders are not balanced in height and/or diameter – a lead insert is set to one diameter and the other is set slightly back, to the wider, desired final diameter. Stepped cutting effectively cuts two larger diameters with two different inserts in one operation. This does affect feed rate, but time is made up in the increased material removal, elimination of tool changes, presetting and programming. When it comes to depth of cut, stepped cutting offers a 60 percent to 100 percent increase in the stock allowance of the twin cutter in its balanced configuration. The setup is best for through-bores, where a stepped profile is no concern.

Stepped cutting is especially effective for long-chipping materials because the staggered cutting reduces chip length. With such a high volume of stock being removed, regardless of material type, chip removal is a key consideration in stepped cutting; high pressure coolant may be necessary. It’s also important to note that a disc will be created at the end of the bore; you’ll have to account for fixturing and you don’t want to run the operation on stacked plates.

Sure, helical interpolation allows for multiple diameters with one tool, but our lineup of twin cutters, for instance, ranges from .787 in to 8.000 in diameter with only eight different heads. For those with even larger jobs, pre-designed solutions are available up to 118 in. As we continue to gain more experience with shop applications over the years, we are more convinced than ever that there isn’t one holemaking challenge that twin cutters can’t answer, especially in production.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.

Add new comment