Fulfilling Modern Micromachining Demands on a Legacy Machine

Looking for a creative way to achieve the requested specifications for a potentially lucrative micromachining job without having to invest in a very expensive specialized machine tool? A spindle speeder may be your best – and only – way to secure the deal.

Most shops are faced with some big questions if approached with an opportunity that involves a part with features that require micro cutting, which generally involves sub-.12 in diameter tooling. Say no to a potentially lucrative job? Or, find a creative way to achieve the requested specifications? If the decision is to “find a way,” then comes the most difficult question: how?

One of the first considerations is generally spindle speed. And unless the shop has a machine capable of high-speed operations, the “how” question becomes even more difficult to answer. Maxing out an existing machine tool is an option, but there are a handful of not-so-small reasons why this isn’t always a good idea, especially for the extended periods often required for the small mold cutting and micro cutting cycles involved here:

- More speed means more friction, which means more heat and the potential for thermal expansion that deteriorates bearings and gears.

- As the heat rises, Z-axis deformation/elongation is almost unavoidable and has a significant effect on micro-cutting accuracy.

- Even when paying careful attention to coolant, lubricant breakdown will happen and require more service and more downtime.

- Shops usually measure runout at a dramatically lower rpm – even statically. Dynamic runout, measured at max speed, can be 10X to 20X higher.

Needless to say, this creates challenges with achieving good chip separation, reasonable tool life, the required surface finish and avoiding built-up edge. The operator can opt to purchase a new and expensive small machine with a high-speed spindle and equip it with smaller tools and holders to facilitate higher rotation rates, HSK sizes 25-32, etc. But this limits larger work and quite literally requires a delicate balance that takes into account the part material’s ideal surface feet per minute (sfm) range, the cutter’s diameter and extremely high rpm. So what does all of this mean for our hypothetical shop?

In my humble opinion, it means that if a shop can’t or doesn’t want to invest in a very expensive specialized machine tool, a spindle speeder may be their best – and only – way to secure the deal. While a spindle speeder is certainly a smaller investment that a specialized machine tool, it’s an investment nonetheless. To make sure it pays off, here are a few things to keep in mind when shopping or testing one out for the first time.

AUTOMATIC TOOL CHANGE (ATC): KEY TO EFFICIENCY

Spindle speeders need to be able to achieve ATC. Operators do not want to have to stop production to hook up lines or activate the system due to tool change. Certain speeders, for instance, only require a single stop block to be attached to the spindle face. That stop block engages a position pin on the tool itself, which serves two purposes. In the case of a gear drive system, it holds the tool steady while the spindle rotates. In the case of an air drive system, the air flows through the stop block.

COLLET CONSIDERATIONS

Regardless of the drive mechanism, most problems associated with high-rpm micromachining are caused by poor dynamic runout of the machine spindle. A cutting tool with only .010 in diameter taking a chip load of less than a tenth per tooth must be managed to better than one tenth. ER systems are not accurate enough for this kind of application. Collets should be inspected for precision and clamping with nuts specialized for high speed with good balance and clamping force. We go as far as to integrate micro collets into our speeders capable of extreme clamping forces down to diameters of .018 in, and in clamping intervals of .004 in. This minimal amount of collapsibility assures a consistent mating of the collet bore against the cutting tool shank and allows for excellent gripping force and low runout.

KNOW YOUR TORQUE

When output speed increases, available torque decreases. As you approach the upper limits of speed, in excess of 100,000 rpm, horsepower at the cut can sink below .5. Do not exceed torque or force depth of cut. Take your time and you’ll be rewarded with beautiful finishes and high precision.

AIR POWER HAS A LOT TO OFFER

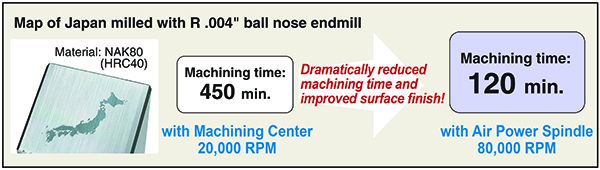

There are three types of spindle speeders: gear driven that reach about 24,000 rpm; electric driven that max out around 80,000 rpm; and air powered, which are faster yet (for example, the RBX12 spindle speeder can reach speeds of 120,000 rpm). In addition to the benefit of speed, because the machine tool spindle doesn’t turn, it saves wear and tear. A lack of heat buildup allows air spindles to run the long cutting cycles common in micromachining. There are also significant cost savings to exhausting air pressure into the atmosphere as opposed to driving the spindle with a motor.

It’s true that there is a lot to consider when implementing spindle speeders, but none of it is unreasonable for the average shop that is trying to land micromachining work. The alternatives on the other hand – a new machine or turning down work – may very well be.

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.