Faster and better machining performance: on existing equipment

Unleashing the hidden potential of existing equipment with BIG-PLUS® spindles

Many machine manufacturers already have the

BIG-PLUS®-capable spindles are characterized by their high performance and backward compatibility with standard tool holders. The

There are 170 licensed machine manufacturers who have taken the decision to use

Thomas Nöth, Managing Director of the sports weapons manufacturer Hera from Lower Franconia in Germany, recognized this potential and acted accordingly. He places great importance on the efficient production of his company's premium products, but under no circumstances would he compromise his high-quality standards to achieve it.

And he doesn’t have to, because state-of-the-art CAD and CAM technology is used in CNC-controlled production processes to ensure both quality and process reliability. Two Milltap 700s milling machines from DMG Mori (with a

40 % time saving, but even the most rigid machining center is of no use unless ....

At just 25, Daniel Krüger is still quite young for a production manager, but having grown up with the company over many years, he has already acquired a great depth of experience.

Daniel has had a decisive influence on Hera’s choice of DMG machines and machining tools from

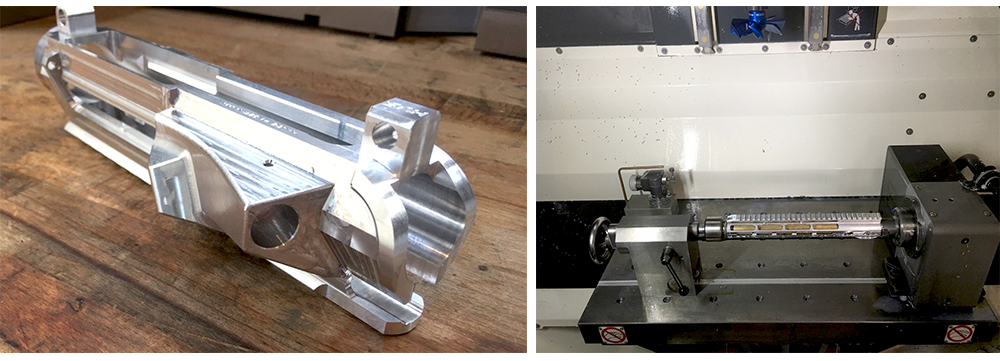

"We receive the AR-15 upper receivers as raw parts which we subsequently mill into their final form,” explains Daniel. “The flawlessness of the 'precision chain' is of utmost importance in this process. From the spindle via the tool holder through the tool and the workpiece into the chuck and back into the machine, everything must be perfectly aligned and run like clockwork. The most rigid machining center is of absolutely no use to me if my tool holder cannot keep up.”

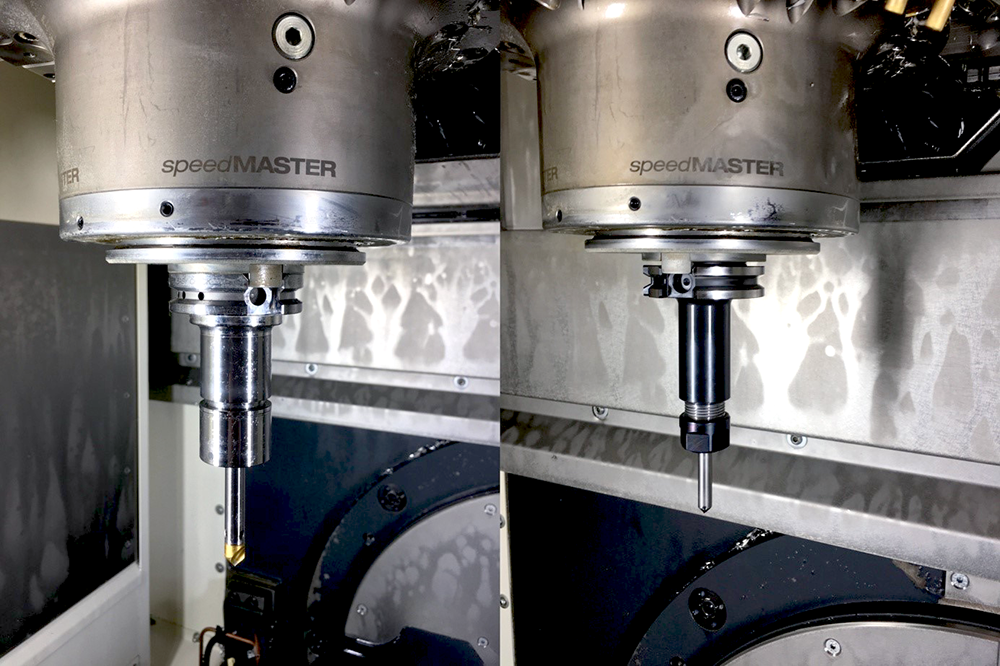

"The DMG machines are ideally suited for this task because their SpeedMASTER spindles use the

The advantage: unlike other machine spindle designs,

"The system really convinced me,” says Daniel. “Not only could we meet our quality requirements but by increasing the feed rate, we could also slash machining time by 40%."

How does BIG-PLUS® work?

Armin Salbaum from BIG KAISER's Application Technology & Production Optimization division explains: "Compared to a standard conical interface, the

“The tool is subsequently drawn into the spindle until its flat surface reaches the surface of the spindle nose,” continues Armin. “That's why it's so important that the holders are within tolerance. If not, as often happens with non-licensed copycat tool holders, the spindle can be severely damaged.”

The

"Basically, I can work with a 30

“There are also situations where the smaller spindle is advantageous, because its reduced size allows it to move closer to difficult components,” says Daniel. “Ever since discovering this, we've been using

Modularity leads to time savings, fewer errors

BIG KAISER's CK interface on these tool holders enables simple replacement using just a single screw, with µm precision.

"This is particularly important for smaller companies like Hera," explains Daniel. "With the CK interface, I can insert extensions and reductions and use them with solid drills, fine boring heads and even drill chucks. I can clamp the whole thing in any tool holder and switch between machines, even though they may have different machine spindles.”

“The modularity that I am able to achieve and the reduction in the number of tools required is simply amazing,” says Daniel. “There are no errors, and we save time and prevent costly mistakes."

Better handling characteristics result in better quality

Hera was also able to effectively optimize its tool inventory management system. Daniel comments, "The nice thing about

“Furthermore, we now achieve better results using a single cutter fine boring head that we always have on hand, rather than the special reamer that always had some procurement and delivery time issues,” adds Daniel. “Within the same machining time, I now have better surface quality and less scrap."

"The

“It goes without saying that there is not always an operator standing at every machine cleaning up everything with a compressed air gun at the end of the machining process,” says Daniel. “We used to have problems with staining but that's now history. We also save both time and compressed air. The manual removal of chips always carries with it the risk of injuries caused by flying chips – that’s another issue that we no longer need to deal with.”

Investment in premium tools pays off

When Hera was founded in 2008, no one ever expected the success that their products would achieve. Just in recent years, Hera has shown such strong growth that a new machining centre has been purchased almost every year.

"As the boss of a small company, I was initially somewhat skeptical about Daniel’s ambitious equipment purchase plans,” says Thomas. “But since we have always placed great importance on the relationship between price and performance, we ultimately decided to use premium tools, and that decision has paid off every single time.”

Did you find this interesting or helpful? Let us know what you think by adding your comments or questions below.