Multi-Axis Systems

When and Where You Need It

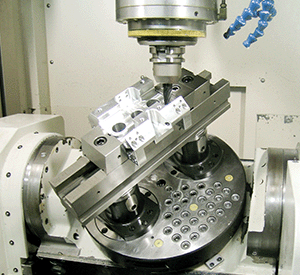

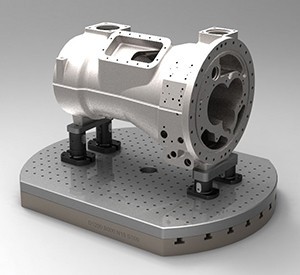

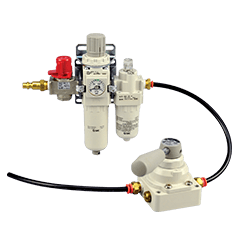

Optimize your multi-axis machining with UNILOCK Multi-Axis Systems. Discover low-profile grid plates featuring integrated UNILOCK zero-point clamping systems, designed for precision work at the machine table center. These turnkey solutions, equipped with cap screw and dowel pin technology alongside UNILOCK zero-point chucks, offer effortless compatibility with a wide range of workholding tools, including multi-axis vises and dovetail clamping options.

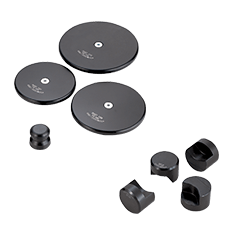

Need to elevate your workpiece above the table? UNILOCK Multi-Axis Systems allow you to raise either the workholding device or the workpiece itself. Utilize UNILOCK clamping knobs, conveniently attachable to the workpieces within 25mm of the machining edge.

For seamless integration, UNILOCK zero-point clamping chucks can be surface-mounted directly onto your machine table. With a slim profile, the UNILOCK ASM 146 and ISM 160 chucks, standing at just 46mm in height, are ideal choices when you require quick-change UNILOCK receivers. Moreover, these multi-axis clamping products, including UNIVICE SYNCHRO, UNICLAMP, and FIRST GRIP, can be effortlessly affixed to your machine table, grid plate, or utilized in UNILOCK chucks. Unlock your machining potential with UNILOCK Multi-Axis Systems.

- Precision: Achieve precise machining with UNILOCK's integrated clamping systems.

- Compatibility: Easily adapt to various workholding tools, including 5-axis vises and dovetail clamping.

- Versatile Elevation: Elevate workpieces or workholding devices to suit your machining needs.

- Convenient Attachment: UNILOCK clamping knobs offer flexible and easy workpiece attachment.

- Space-Saving Design: Slim-profile chucks save space and provide quick-change capabilities.

- Efficient Machining: UNILOCK's versatile clamping products enhance machining efficiency.